MENUMENU

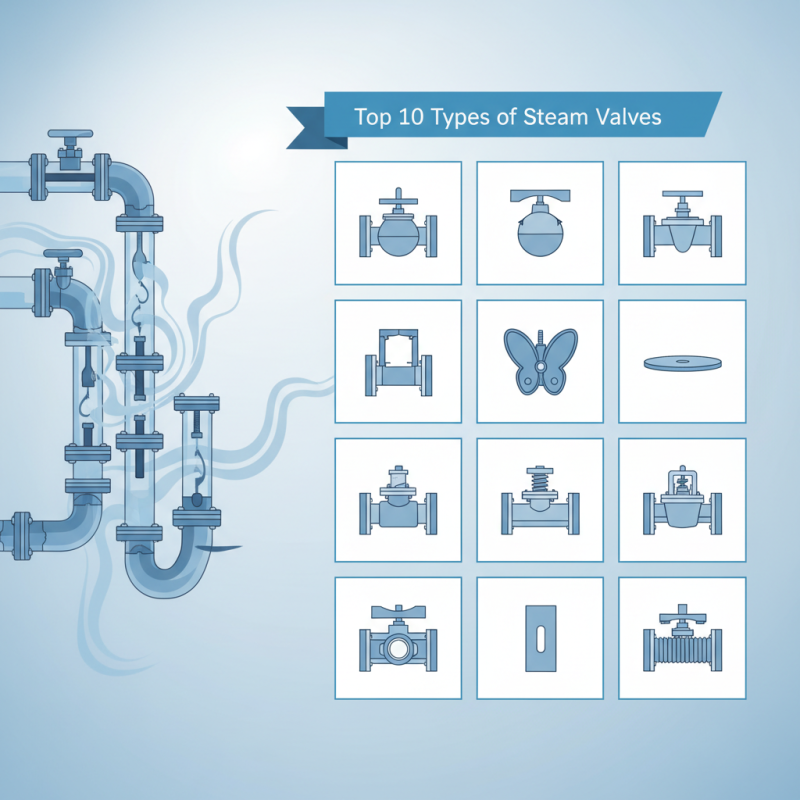

In the world of industrial applications, steam valves play a crucial role in ensuring efficient and safe operation of systems that rely on steam for energy transfer. According to the latest report from the Global Valve Market Analysis, the steam valve segment alone is projected to grow at a compounded annual growth rate (CAGR) of 6.4% from 2022 to 2027, reflecting the increasing demand in various sectors such as power generation, chemical processing, and manufacturing. This surge emphasizes the importance of understanding the various types and functionalities of steam valves to optimize projects effectively.

Industry expert Dr. Alan Cooper, a leading authority on valve technologies, highlights the significance of these components: "The right steam valve selection can greatly enhance process reliability and contribute to energy efficiency." With multiple designs available, ranging from globe valves to ball valves, each type presents unique characteristics suited to specific applications.

As engineers and project managers face mounting pressure to minimize operational costs while maximizing efficiency, a thorough knowledge of the top ten types of steam valves becomes indispensable. This understanding not only aids in selecting the appropriate valve but also promotes overall system performance, ultimately leading to successful project outcomes.

Steam valves are essential components in various industrial processes, serving critical roles in regulating and directing the flow of steam throughout systems. Understanding the different types of steam valves is paramount for engineers and project managers to ensure safety, efficiency, and reliability in operations. According to industry reports, improper valve selection can lead to oversized equipment, increased operational costs, and potential system failures, highlighting the importance of comprehensive knowledge in valve types and their functions.

The primary types of steam valves include gate valves, globe valves, ball valves, and check valves, each designed for specific applications. For instance, gate valves are often used for on/off control with minimal pressure drop, while globe valves provide better throttling capabilities. Recent studies indicate that an estimated 30% of steam system energy consumption can be directly attributed to valve inefficiencies, underscoring the significance of selecting the right type for your project. Moreover, with the rising costs of energy and the push for sustainable practices, the correct implementation of steam valves can contribute to energy savings of up to 20%, according to the U.S. Department of Energy's findings on steam system optimization.

Choosing the appropriate steam valve not only enhances system performance but also plays a crucial role in maintenance and operational longevity. Faulty valve selections can lead to leakages and costly downtime, emphasizing the need for careful evaluation of valve specifications and their compatibility with system requirements. In conclusion, a well-informed selection process for steam valves can lead to improved efficiency, reduced costs, and increased operational resilience, making it an integral part of any project involving steam systems.

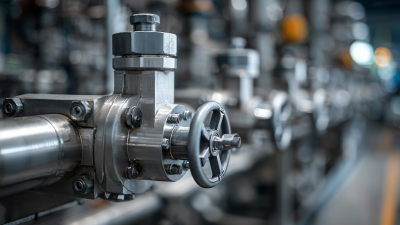

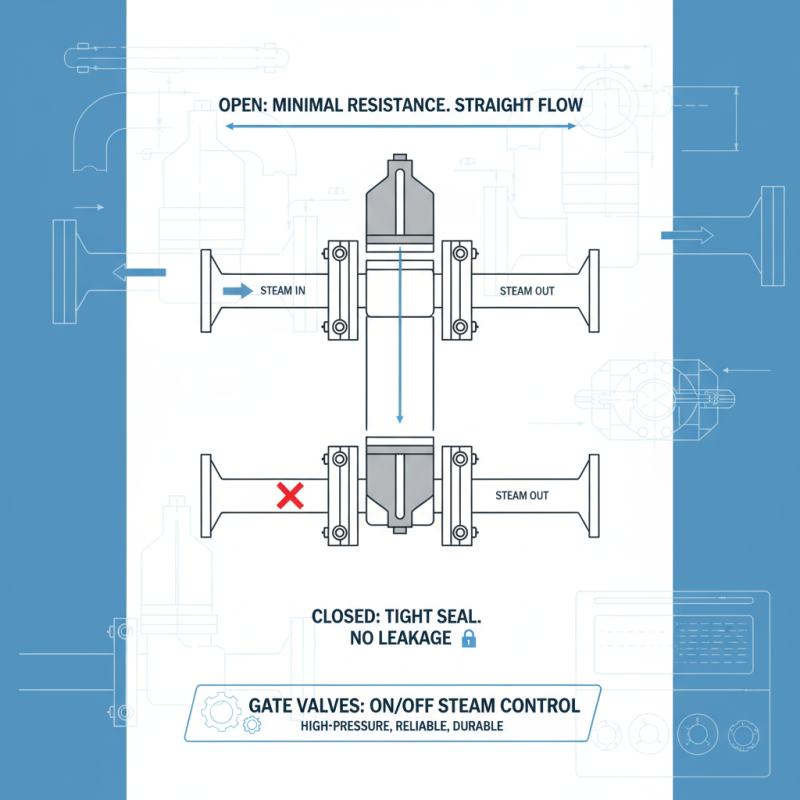

Gate valves are a crucial component in steam systems, primarily serving the purpose of on/off control. These valves are designed to provide minimal resistance to the flow of steam when fully opened, making them ideal for applications that require a straight-line flow of fluid. By utilizing a wedge-shaped gate that moves up and down within the valve body, gate valves ensure that the seal is tight when closed, effectively preventing steam leakage. Their simplistic design and robust construction make them suitable for high-pressure steam applications, where reliability and durability are paramount.

Another significant advantage of gate valves is their ease of operation and maintenance. With a straightforward handwheel or actuator control, operators can quickly shut off or restore the flow of steam, making them ideal for situations where rapid response is necessary. Additionally, gate valves are available in various materials to suit different types of steam environments, providing versatility for engineers and project managers. As steam systems often require frequent cycling between open and closed states, understanding the functionality and application of gate valves can lead to more efficient system designs and enhanced overall performance.

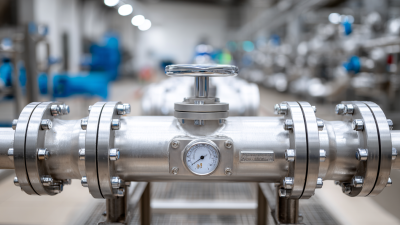

Globe valves are a critical component in many steam applications, particularly when precise flow regulation and throttling are required. Their design, which features a spherical body shape, allows for a more controlled flow path, making them ideal for processes where adjustments must be carefully managed. The configuration of the globe valve creates a significant pressure drop, which, while generally undesirable for many systems, is beneficial in applications where reducing flow is necessary to maintain system stability.

When implementing globe valves, several best practices should be observed. First, proper sizing is crucial; an oversized valve can lead to flow instability and noise, while an undersized valve may not provide adequate throttling capabilities. Additionally, installing globe valves in the correct orientation is vital, as they are typically designed for vertical installation to prevent water hammer and ensure optimal performance. Regular maintenance is also essential; checking for leaks and ensuring the sealing surfaces are in good condition will prolong the valve's life and maintain system efficiency. By adhering to these best practices, engineers can enhance the reliability and functionality of their steam systems.

| Valve Type | Best Practices | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Globe Valve | Use for throttling and flow regulation. Maintain regular checks and cleaning. | Pipelines, cooling systems, HVAC applications | Excellent flow regulation, long lifespan | Higher pressure drop, requires more space |

| Ball Valve | Ideal for on/off applications, ensure the ball rotates freely. | Water supply systems, gas pipelines | Minimal pressure drop, quick operation | Not suitable for throttling, can be more expensive |

| Gate Valve | Use for fully open or closed positions, do not use for throttling. | Long pipelines, water treatment facilities | Low friction loss, suitable for large volumes | Slow to operate, may require more torque |

| Check Valve | Install in a horizontal position to prevent backflow. | Pumping systems, sewage systems | Prevents backflow, compact design | Limited throttling ability, can cause water hammer |

| Butterfly Valve | Use for quick shutoff, check alignment to prevent leaks. | Water distribution, HVAC | Lightweight, quick operation | Not suitable for high-pressure systems, limited throttling control |

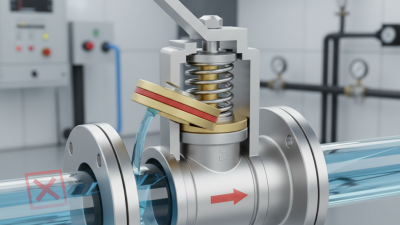

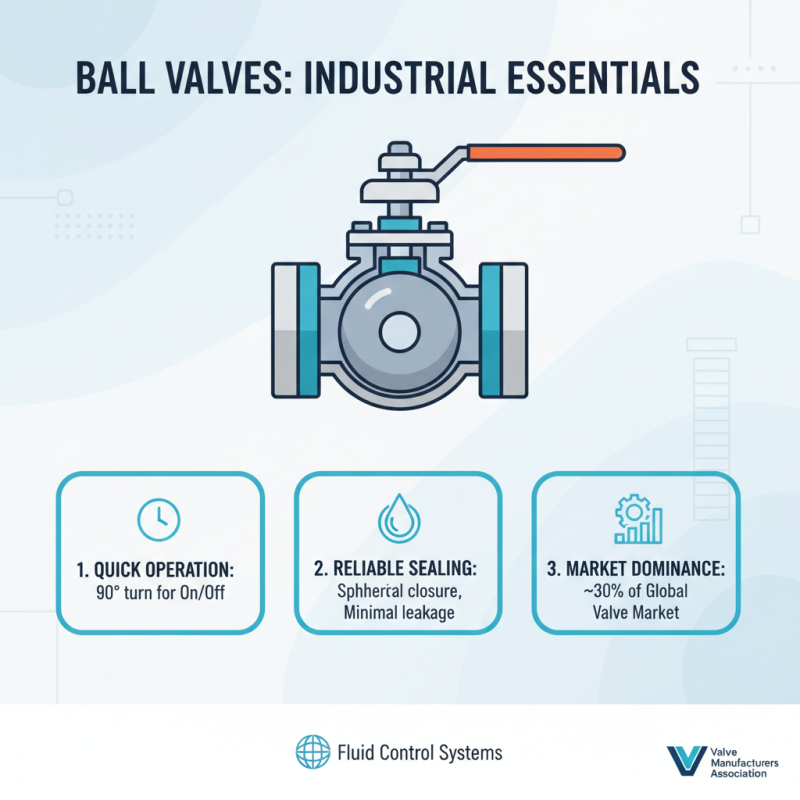

Ball valves are essential components in various industrial applications, primarily due to their advantages in quick operation and reliable sealing. Unlike other valve types, ball valves achieve tight sealing through a solid, spherical closure element that ensures minimal leakage even in high-pressure scenarios. According to a report by the Valve Manufacturers Association, ball valves represent approximately 30% of the global valve market, underscoring their widespread use and importance in fluid control systems.

One compelling reason to choose ball valves is their ability to operate quickly—often requiring only a quarter turn to open or close. This characteristic is particularly advantageous in processes where rapid action is crucial. Furthermore, the durable design of ball valves minimizes wear and tear, leading to longer service life compared to traditional valves. The same report indicates that efficient sealing mechanisms can reduce operational costs by decreasing the incidence of leaks, ultimately contributing to more sustainable operational practices.

Tips: When selecting ball valves for your projects, consider the specific application requirements such as temperature, pressure, and the type of fluid being controlled. It's also beneficial to evaluate the material of the valve to ensure compatibility and longevity under operational conditions. Regular maintenance checks can further enhance the performance and reliability of the valve system, safeguarding against potential failures.

In steam applications, ensuring the integrity of the system is crucial, and check valves play a vital role in preventing backflow. These valves automatically close to stop the reverse flow of steam, which can lead to system inefficiencies and potential hazards. According to industry data, improper backflow prevention can result in equipment damage, increased maintenance costs, and compromised system safety—issues that can altogether raise operational costs by up to 30%. Thus, the implementation of check valves is not only a preventive measure but a necessary aspect of steam system design.

When selecting check valves for your steam projects, consider the valve type that best suits your application needs, such as swing check valves or spring-loaded check valves. Each type offers different benefits in terms of pressure drop and flow characteristics. It's essential to ensure that the valve material is compatible with the operating conditions, as this impacts both durability and performance.

Tips: Always consult the manufacturer’s specifications and operational guidelines to identify the most suitable check valve for your steam system. Regular maintenance and inspections of these valves can also prevent unexpected failures and prolong the lifecycle of your steam system. Be proactive in your approach to backflow prevention, as this can significantly enhance efficiency and safety across your operations.