MENUMENU

In the ever-evolving landscape of industrial applications, the performance of check valves remains a critical factor for operational efficiency. As industries seek to optimize their systems, understanding the future of check valve technology and its applications becomes essential. Check valves play a pivotal role in ensuring fluid control and preventing backflow, thereby safeguarding equipment and enhancing overall productivity. This blog will explore top strategies for enhancing check valve performance, examining innovations in materials, design improvements, and maintenance practices that can lead to more reliable and efficient operations. By delving into these strategies, we aim to equip industry professionals with the knowledge needed to leverage the full potential of check valves in their processes, ensuring robust performance in a competitive environment.

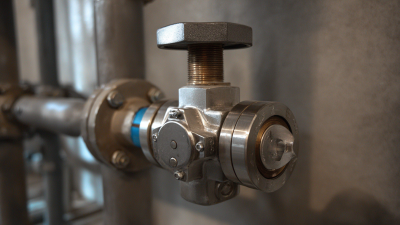

Check valves are essential components in various industrial applications, designed to allow flow in one direction while preventing backflow. Understanding the different types and designs of check valves is crucial for optimizing their performance.

The two main categories of check valves are spring-loaded and weight-assisted designs. Spring-loaded check valves use a spring mechanism to close the valve when there is no flow, making them ideal for applications with fluctuating pressures. These valves are commonly found in pumping systems and water treatment facilities.

On the other hand, weight-assisted check valves rely on gravity or a weighted disk to close the valve, which is more suited for applications where the flow is consistently unilateral, such as in gravity-fed systems. These valves are essential in sewer systems and drainage, where backflow can lead to severe operational disruptions. Other specialized designs, such as dual-plate and wafer check valves, offer unique benefits in terms of space-saving and enhanced sealing, making them suitable for high-pressure environments. Understanding these various designs enables engineers to select the appropriate check valve for optimal performance in specific industrial applications.

In industrial applications, the efficiency of check valves is crucial for maintaining optimal system performance. Key performance metrics for evaluating check valve efficiency include flow rate, pressure drop, and response time. A well-designed check valve should allow for smooth fluid passage while preventing backflow, ensuring minimal energy loss. Regular assessments of these metrics can help identify any potential issues before they escalate, allowing for timely interventions and maintenance.

Another important aspect to consider is the valve's material compatibility with the fluids they are designed to handle. Factors such as temperature, pressure, and the nature of the fluid can significantly influence a check valve's performance. By monitoring wear and corrosion rates, industrial operators can determine when a valve may need replacement or repair, thereby maintaining the overall integrity of the system. Focusing on these performance metrics not only enhances the reliability of check valves but also contributes to increased operational efficiency and reduced downtime in industrial settings.

Material selection plays a pivotal role in optimizing the performance of check valves in industrial applications. The choice of materials directly influences factors such as corrosion resistance, pressure tolerance, and overall lifespan. For instance, stainless steel is often favored for its excellent resistance to a wide range of corrosive substances, while materials like brass and PVC might be selected for specific fluid dynamics and cost considerations. According to a recent report from the Flow Control Association, using the appropriate materials can enhance a check valve's performance by up to 30%, significantly reducing maintenance costs and downtime.

Tips for successful material selection include conducting a thorough analysis of the fluid characteristics, including its pH level, temperature, and viscosity. Choosing elastomers for seals that can withstand the specific temperatures and chemicals involved will also extend the valve's operational life. Moreover, looking into industry-specific standards, such as those from ASTM or ISO, ensures compliance and optimal performance tailored to the application.

In addition, regular inspection and maintenance can prevent material degradation. Utilizing predictive maintenance technologies such as vibration analysis and temperature monitoring can help identify potential failures before they affect performance. By strategically selecting the right materials and implementing proactive maintenance plans, industries can maximize the efficiency and reliability of their check valves.

Check valves are critical components in various industrial systems, ensuring that fluid flows in the desired direction and preventing backflow. However, many operations face challenges with check valve performance, often leading to costly downtime and maintenance. According to a report by the American Society of Mechanical Engineers, nearly 30% of all valve failures in industrial applications are attributed to check valves primarily due to improper installation, material incompatibility, and sediment buildup.

Troubleshooting these failures begins with identifying common issues. One prevalent problem is seat leakage, which can occur from wear or debris collection, causing inefficient sealing and allowing reverse flow. Regular inspections coupled with advanced techniques such as non-destructive testing can help detect issues before they lead to significant failures. Furthermore, selecting the right materials and employing modern designs such as spring-assisted check valves can significantly mitigate these common issues, enhancing overall performance. Industry studies suggest that implementing proactive maintenance can reduce valve-related downtime by up to 25%, showcasing the importance of addressing these vulnerabilities promptly.

This bar chart illustrates the key performance metrics associated with check valves in industrial applications. The metrics include pressure loss, flow rate, maintenance frequency, and failure rate, which can provide insights into the common issues and troubleshooting strategies for enhancing check valve performance.

Innovative technologies are revolutionizing the design and functionality of check valves, particularly in industrial applications where reliability and performance are critical. Recent advancements include the incorporation of advanced materials such as corrosion-resistant alloys and robust polymers, which significantly enhance the longevity and effectiveness of these valves. According to a report by the Global Check Valve Market Research, the use of high-performance materials can increase the operational lifespan of check valves by up to 30%, thereby reducing maintenance costs for industries that rely heavily on these components.

Furthermore, modern manufacturing techniques such as 3D printing and precision machining are enabling the production of check valves with intricate designs that improve flow efficiency and reduce turbulence. A study conducted by the Industrial Flow Control Consortium indicates that optimally designed check valves can enhance flow rates by up to 15%, leading to better energy efficiency in systems such as HVAC and water treatment plants. These advancements not only contribute to operational efficiency but also align with sustainability goals by minimizing energy consumption and waste in industrial processes.