MENUMENU

In the ever-evolving landscape of industrial applications, selecting the best tank valve is crucial for ensuring operational efficiency and safety. The global tank valve market is projected to grow significantly, reaching an estimated value of $4.5 billion by 2025, according to recent industry reports. With advancements in materials and technologies, such as the integration of smart monitoring systems, choosing the right type of tank valve has become more complex. Factors such as compatibility with various fluids, pressure ratings, and regulatory compliance can heavily influence the decision-making process. As businesses strive for sustainable solutions and enhanced performance, understanding the specific requirements for tank valve applications is essential to optimizing overall system reliability. This blog will explore the top strategies for selecting the best tank valve, considering current industry trends and future solutions.

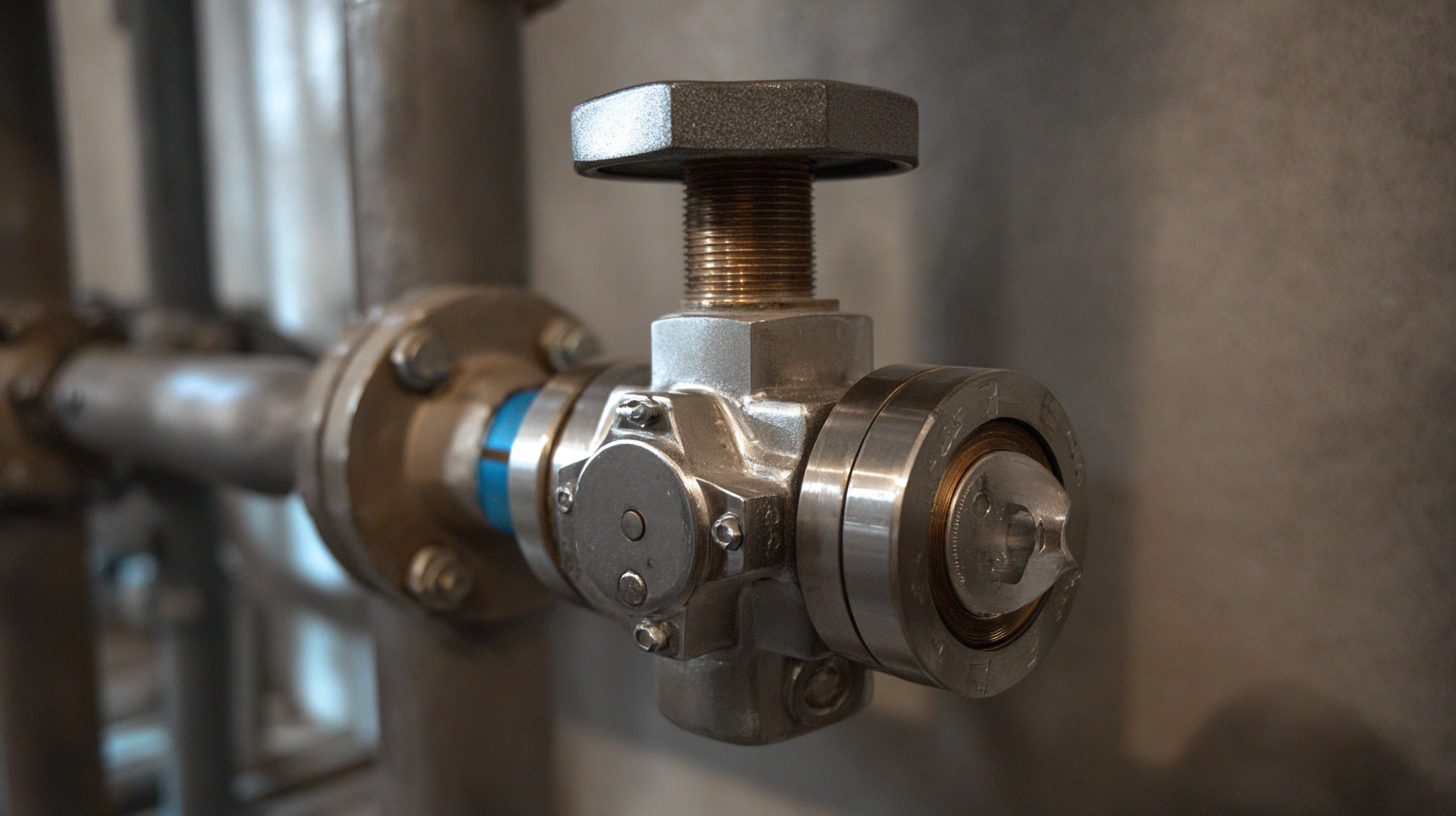

When selecting a tank valve, material choice is crucial, as it directly affects the valve's performance, durability, and suitability for specific applications. Different materials offer various properties that can enhance or hinder the valve's function. For instance, stainless steel valves are well-known for their corrosion resistance and strength, making them ideal for high-pressure and chemically aggressive environments. Conversely, plastic valves may be more suitable for applications involving non-corrosive liquids but may lack the structural integrity required for high-stress scenarios.

Understanding the operating conditions is essential in material selection. Factors such as temperature, pressure, and the chemical nature of the fluid being handled play a significant role in determining which material is best suited for a tank valve. For example, in applications with extreme temperatures or aggressive chemicals, using specialized alloys or high-performance plastics can prevent premature wear and failure. Therefore, thorough research and consideration of these variables will lead to informed decisions when choosing tank valves, ensuring they meet both regulatory standards and operational efficiency.

When selecting the best tank valve, one of the most critical aspects to consider is the flow requirements, which encompass both sizing and pressure considerations. Understanding the flow rate necessary for your specific application is paramount; it not only affects the performance of the valve but also impacts the efficiency of the overall system. An inadequate flow rate can lead to bottlenecks and insufficient tank drainage or filling, while excessive flow may cause turbulence, noise, and potential damage to the system. Therefore, calculating the desired flow rate based on the tank's size and use case is the first step in selecting the appropriate valve.

Pressure considerations are equally important in the valve selection process. Valves must be able to withstand the operating pressure of the system without compromising safety or functionality. It's essential to evaluate both the static and dynamic pressures involved, as these will influence the type of valve material and design. Overlooked pressure ratings can lead to valve failure or leaks, resulting in costly downtime. By thoroughly assessing the flow rate and pressure requirements, one can ensure a seamless integration of the valve into the system, ultimately enhancing performance and reliability.

When selecting the best tank valve for your needs, a thorough comparative analysis of different valve designs is crucial to achieve optimal performance. Recent studies have highlighted the importance of design parameters in various applications, such as pressure-maintaining ball valves and pneumatic control systems. For instance, the structural integrity and flow characteristics of these valves can significantly influence their pressure-holding capacity and control responsiveness. Understanding these factors allows for selecting valves that not only meet operational requirements but also enhance system efficiency.

Moreover, innovations like the multistage Tesla valves, which utilize staggered alternatingly oriented flow baffles, provide intriguing possibilities for improving fluid dynamics and performance in heat exchangers. This principle can extend to tank valve selection, where the integration of advanced design concepts could streamline flow and reduce operational issues such as cavitation and noise. By leveraging a comparative approach and considering cutting-edge designs, one can identify the most appropriate valve that aligns with specific operational demands and enhances overall system performance.

When selecting a tank valve, understanding the role of certifications and standards is crucial for ensuring quality and safety. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of industrial failures can be traced back to inadequate compliance with standards. This underscores the importance of choosing valves that meet recognized certifications such as API, ASTM, and ISO, which provide assurance that the valve can withstand operational pressures and harsh chemical environments.

Certifications often reflect a valve's construction quality, testing protocols, and material integrity. For instance, valves with ISO 9001 certification indicate a commitment to quality management systems. Moreover, a survey conducted by the Valve Manufacturers Association (VMA) revealed that 95% of companies prefer suppliers whose products adhere to strict industry standards. This preference not only ensures reliability but also increases the longevity of the equipment, which is estimated to save companies about 12% in annual maintenance costs. By prioritizing certified tank valves, businesses can effectively mitigate risks and enhance operational efficiency.

When considering the balance between cost and quality in selecting the best tank valve, it’s essential to understand the various cost factors at play. According to industry reports, the average cost of tank valves can range from $50 to over $500, influenced by the materials used, the complexity of design, and additional features such as automated controls.

Simultaneously, recent studies indicate that opting for higher quality components can lead to a 30% reduction in maintenance costs over five years, emphasizing that investing in quality can ultimately be more economical.

Budgeting strategies play a crucial role in navigating these decisions. Companies should conduct a thorough analysis of their operational needs, aligning their budget with performance targets. For example, a comprehensive survey highlighted that organizations prioritizing high-performance valves reported enhanced operational efficiency up to 25%.

Implementing a phased purchasing strategy can be effective; acquiring essential components first while planning for upgrades later allows businesses to spread costs over time without sacrificing quality. Balancing budget constraints with performance needs requires a strategic approach, ensuring investments yield long-term benefits.