MENUMENU

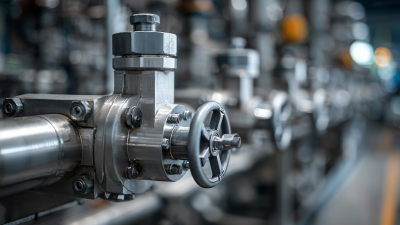

Selecting the right process valve is a crucial decision for any industrial operation, as it directly impacts efficiency, safety, and overall system performance. Process valves play a vital role in controlling the flow of fluids, gases, and slurries in various applications, from manufacturing to chemical processing. With a myriad of options available in the market, understanding the different types of valves, their configurations, and materials is essential for making an informed choice. Factors such as pressure ratings, temperature ranges, and the specific nature of the media being transported must be considered to ensure that the selected valve not only meets operational requirements but also complies with industry standards. This guide aims to provide practical insights and strategies for selecting the most suitable process valve for your unique industrial needs, ensuring optimal functionality and longevity in your systems.

Selecting the right process valve for industrial applications is crucial for ensuring efficiency and safety within operational systems. Key factors to consider include the type of fluid being controlled, pressure and temperature conditions, and the valve's material compatibility. According to a report by the International Society for Automation, approximately 30% of industrial process failures are attributed to incorrect valve selection, underscoring the importance of thorough evaluation.

Tips for selecting the ideal process valve include evaluating the flow characteristics of the fluid, which requires knowledge of its viscosity and density. Additionally, consider the environment in which the valve will operate; corrosive substances demand materials that withstand such conditions, while high-pressure systems may require valves with enhanced structural integrity. A recent study indicated that choosing the wrong valve type can lead to a 20% increase in maintenance costs over time, showcasing the economic impact of informed selection.

Moreover, investing in valves with smart technology capabilities can lead to better performance monitoring and predictive maintenance. A report from Transparency Market Research highlights a projected growth in smart valves, with a CAGR of 12.5% between 2021 and 2028, demonstrating a clear trend towards advanced solutions in the industry. By keeping these factors in mind, industries can significantly improve their operational efficiency and reduce costs.

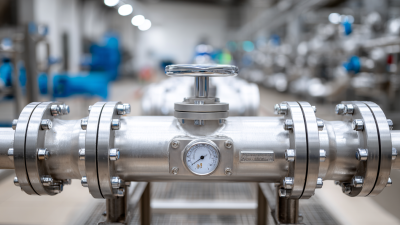

When selecting the right process valve for industrial applications, it is crucial to understand the different types available and their specific uses. One common type is the globe valve, which is known for its excellent throttling capabilities. This valve type is ideal for applications requiring precise flow control, such as in chemical processing and heating systems. With its disc and seat design, the globe valve effectively regulates flow, making it suitable for processes that demand consistent performance.

Another prevalent type of process valve is the ball valve, recognized for its durability and quick operation. Ball valves are often used in on/off applications due to their ability to fully open or close with minimal pressure drop. Industries that require secure shut-off valves, such as oil and gas, frequently utilize ball valves for their reliability and ease of maintenance. Additionally, we have butterfly valves, which are perfect for large volume flow regulation. Their quarter-turn operation allows for swift adjustments, making them valuable in HVAC systems and water treatment facilities. By understanding these distinctions, industrial operators can make informed decisions that enhance efficiency and safety in their processes.

This chart displays different types of process valves commonly used in industrial applications and their respective uses.

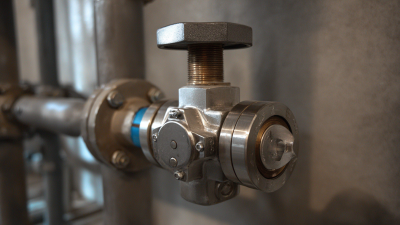

When selecting a process valve for industrial applications, evaluating material compatibility and performance characteristics is crucial. The materials used in valve construction must align with the specific fluid being controlled, as this affects durability and performance. For example, corrosive substances may necessitate the use of stainless steel or specialized alloys, while less aggressive fluids might be manageable with more common materials like PVC or cast iron.

Tips: Always begin by identifying the chemical properties of the fluids involved, including pH levels, temperature, and pressure. This information will guide you toward selecting a material that can withstand the operating conditions without degrading. Additionally, consider the physical environment where the valve will be installed, such as exposure to extreme temperatures or vibrations.

Performance characteristics are another vital aspect to review during selection. This includes the valve's flow coefficient (Cv), leakage rates, and actuator compatibility. A well-chosen valve not only maintains operational efficiency but also reduces maintenance costs over time.

Tips: Test the flow and performance of similar valves in your application, if possible, to determine the best fit before making a final decision. Furthermore, consulting with manufacturers can provide insights into long-term reliability based on material selection and design features tailored to your operational needs.

When selecting the right process valve for your industrial needs, understanding the sizing and flow requirements is crucial. Proper valve sizing ensures that your system operates efficiently, avoiding issues like pressure drops or inadequate flow. To calculate the correct valve size, you must first gather essential data, including the type of fluid, flow rate, and system pressure. These factors will help you determine the required valve diameter to maintain optimal performance.

One common method for calculating valve size is using the flow coefficient (Cv) formula, which relates the flow rate through the valve to the pressure drop. By determining the desired flow rate and the anticipated pressure drop across the valve, you can effectively calculate the Cv and subsequently select a valve that meets these specifications. Additionally, it is vital to consider the fluid's properties, such as viscosity and temperature, as they can significantly impact the valve's performance. Properly sizing your valve not only maximizes efficiency but also prolongs the life of your equipment, ensuring a smooth operation in your industrial environment.

| Valve Type | Maximum Flow Rate (GPM) | Pressure Drop (psi) | Size (inches) | Suitable Applications |

|---|---|---|---|---|

| Ball Valve | 10-100 | 5-30 | 1-6 | Water, Oil, Gas |

| Gate Valve | 20-300 | 10-50 | 2-10 | Oil and Gas, Water Supply |

| Globe Valve | 5-75 | 5-40 | 1-8 | Flow Regulation |

| Check Valve | 15-150 | 5-25 | 2-12 | Prevention of Backflow |

Selecting the right process valve is crucial for ensuring optimal performance and reliability in industrial applications. When considering maintenance and lifespan, it’s essential to choose valves that not only meet operational demands but also support long-term functionality. Regular maintenance can drastically extend the lifespan of valves, reducing unexpected downtimes and operational costs.

Tips: Schedule routine inspections to check for wear and tear, and replace seals and gaskets as needed. Implementing a preventive maintenance program can also help identify potential issues before they lead to valve failure.

Additionally, consider the environment in which the valve operates. Valves exposed to extreme temperatures, corrosive substances, or other challenging conditions may require specialized materials or coatings. This selection can significantly impact both maintenance frequency and overall durability.

Tips: Use valve covers or protective coatings to enhance resistance to environmental factors. Be vigilant about leaks and unusual noises, as they can indicate potential problems that need immediate attention.