MENUMENU

When it comes to industrial applications, selecting the right valve is crucial for ensuring efficiency and reliability in your systems. Among the various options available, the knife valve stands out for its unique design and functionality, making it suitable for a wide range of uses. This blog explores seven key reasons why opting for the best knife valve can significantly enhance your industrial operations. From handling abrasive materials to providing a tight seal, knife valves offer distinct advantages that can improve performance and durability. Understanding the characteristics and appropriate applications of knife valves is essential for making an informed decision, as this choice can ultimately impact operational efficiency, safety, and maintenance costs.

In the following sections, we will dive into the essential features and benefits that make knife valves an indispensable component in many industrial settings.

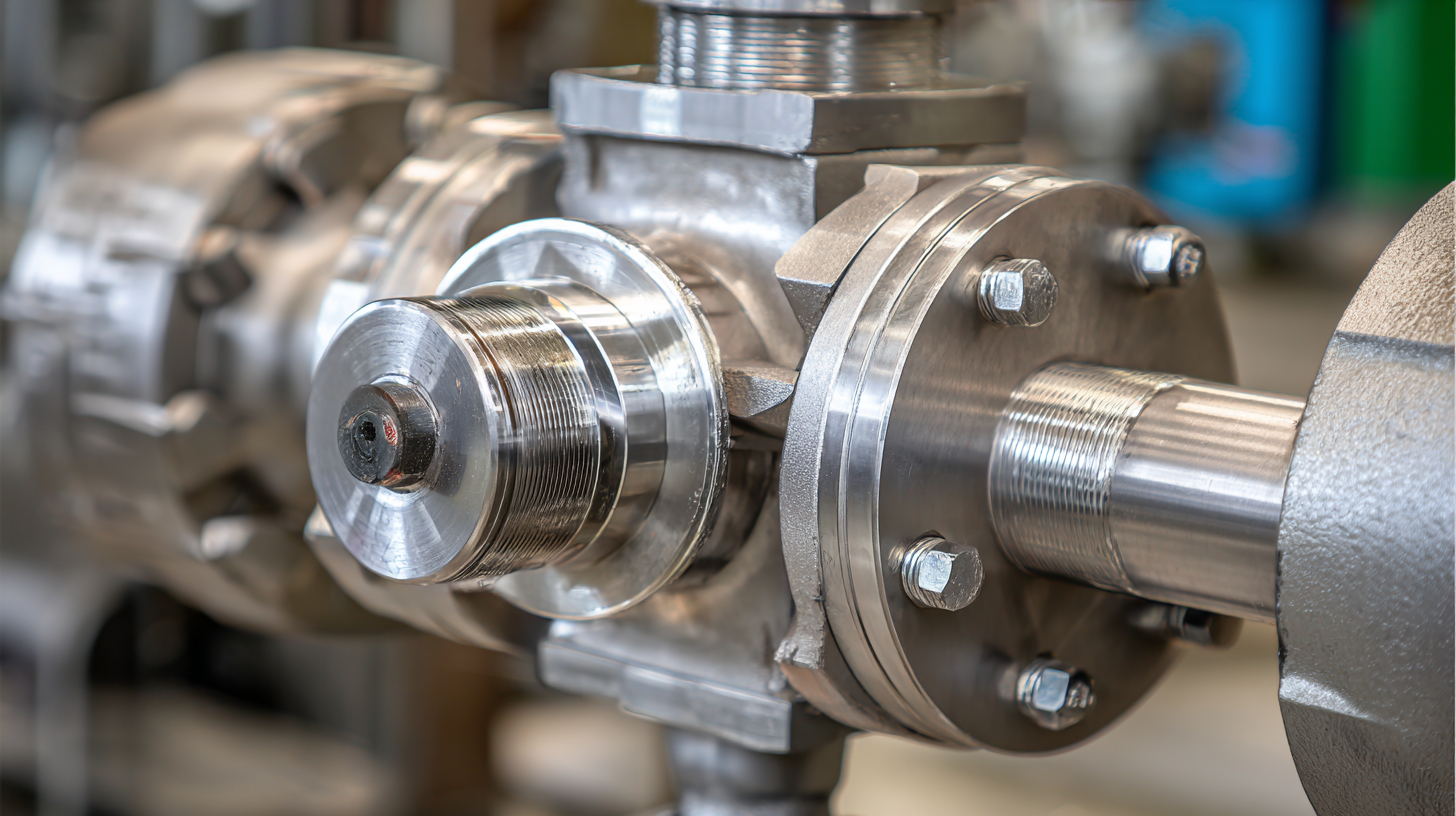

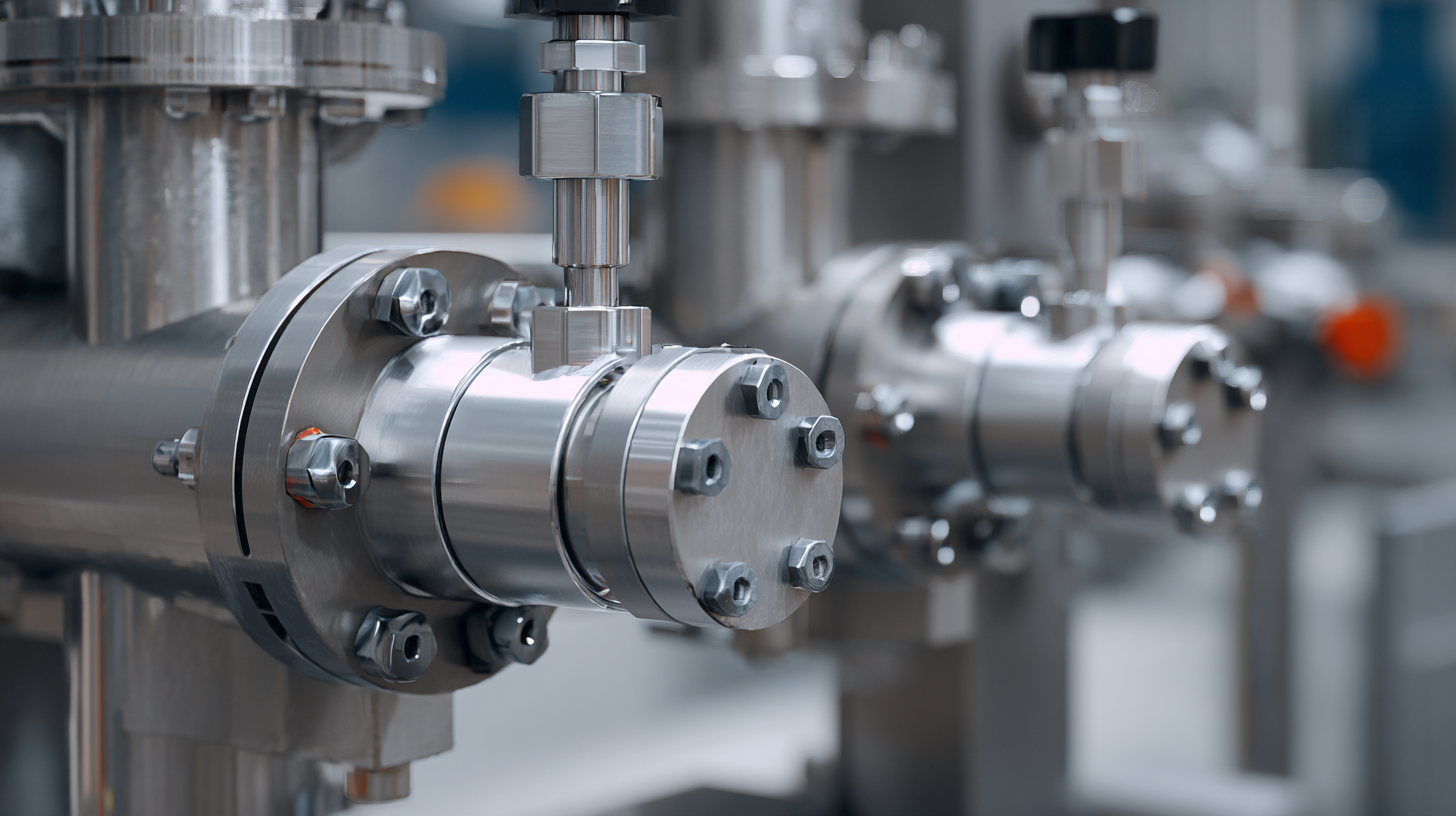

Knife valves are essential components in many industrial applications, particularly in handling slurries, powders, and other thick materials. One of the key features of knife valves is their design, which includes a sharp-edged blade that can effectively cut through the medium, ensuring a tight seal when closed. This capability minimizes leakage and prevents contamination, making them highly reliable for processes involving critical materials.

Another notable benefit of knife valves is their versatility in operation. They can be used in both on-off and throttling applications, allowing for precise flow control. This flexibility is particularly valuable in industries such as pulp and paper, wastewater treatment, and food processing, where the nature of the material can vary significantly. Additionally, the durability of knife valves, often made from robust materials, ensures they can withstand harsh conditions, reducing maintenance costs and extending service life in demanding industrial settings.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Constructed from robust materials that withstand harsh environments. | Longer lifespan reduces replacement costs and downtime. |

| Seal Integrity | Features effective sealing mechanisms to prevent leaks. | Enhances safety and efficiency in operations. |

| Versatility | Suitable for various media including liquids, slurries, and gases. | Flexible use across different applications, reducing the need for multiple valve types. |

| Low Maintenance | Designed for minimal upkeep and easy servicing. | Saves time and cost on maintenance activities. |

| Flow Control | Provides precise control over fluid flow rates. | Improves system efficiency and performance. |

| Temperature and Pressure Handling | Capable of operating under extreme temperature and pressure conditions. | Expands application range in demanding industrial settings. |

| Cost-Effectiveness | Offers a good balance between durability and price. | Increases ROI due to reduced operational costs. |

When selecting a knife valve for industrial applications, one of the most critical considerations is the material construction. The choice of material not only impacts the valve's performance but also its longevity and suitability for specific environments. Common materials for knife valves include stainless steel, carbon steel, and various alloys, each offering unique advantages. Stainless steel, for instance, is widely favored for its excellent corrosion resistance and ability to withstand high temperatures, making it ideal for chemical processing and food industries. In contrast, carbon steel might be more appropriate for applications where cost efficiency is a priority, provided that the operating conditions do not risk corrosion.

Furthermore, specialized alloys such as hastelloy or titanium are often employed in extreme situations where the medium is highly abrasive or chemically reactive. These materials ensure that the valve maintains operational integrity under harsh conditions, prolonging service life and decreasing the need for frequent replacements. The decision to utilize one material over another will depend on factors including the type of media being controlled, temperature fluctuations, and pressure levels. By carefully comparing these material options, industries can optimize their knife valve selection to enhance both performance and reliability.

When it comes to industrial applications, the choice of valve is crucial for operational efficiency and reliability. Knife valves have been noted for their superior performance in handling thick, slurries and viscous fluids. According to a recent report by the Flow Control Institute, knife valves outperform traditional gate valves by 30% in terms of minimizing leakage and providing a tighter seal under high pressure conditions. This is largely due to their unique design, which includes a sharp-edged blade that slices through materials, providing a clean shut-off that prevents clogs.

In contrast, when evaluating performance against other valve types, such as ball or butterfly valves, knife valves excel in environments where solid particles are a concern. A study by the Valve Manufacturers Association revealed that knife valves can reduce maintenance costs by 25% over time compared to ball valves due to their robust design and less frequent need for replacement parts. This makes them an ideal choice for industries that handle abrasive materials, such as mining and wastewater treatment, where durability and long-term performance are essential.

When considering knife valves for industrial applications, a critical factor is their life cycle cost (LCC). According to a report by the International Valve Manufacturers Association (IVMA), the LCC of a valve can account for nearly 70% of its total cost over its operational lifetime. This includes not just the initial purchase price but also maintenance, energy consumption, and potential production downtime.

Knife valves, known for their ability to handle viscous and abrasive materials, often demonstrate lower wear rates and longer service intervals compared to traditional valves, reducing overall maintenance costs.

Furthermore, a detailed analysis conducted by the American Society of Mechanical Engineers (ASME) highlights that high-quality knife valves can result in significant savings in energy costs. Efficient sealing features in knife valves minimize leakages, which has been shown to reduce energy waste by up to 20%. Additionally, the durability of these valves translates to fewer replacements over time, further enhancing their cost-effectiveness. Overall, investing in the best knife valves not only streamlines operations but also optimizes financial resources in the long run.

When selecting a knife valve for industrial applications, compatibility and installation considerations play a crucial role in ensuring optimal performance and longevity. Knife valves are designed to handle slurries, solids, and viscous fluids, making them ideal for industries such as mining, waste management, and chemical processing. According to a report by Research and Markets, the global valve market is expected to reach USD 107.8 billion by 2025, with knife valves projected to experience significant growth due to their versatility and reliability in demanding environments.

Proper installation is essential for achieving the best performance from knife valves. Factors such as flange compatibility, valve orientation, and the material of construction can impact both the operational efficiency and safety of the system. For instance, a study by the Valve Manufacturers Association indicates that ensuring the correct alignment of the valve with piping systems reduces wear and tear, ultimately extending service life by up to 30%. Additionally, understanding the coating and sealing options available can help mitigate issues related to corrosion and erosion, which are critical in harsh industrial settings. Ensuring these considerations are met not only enhances functionality but also supports regulatory compliance within various industrial sectors.