MENUMENU

In the evolving landscape of industrial applications, the significance of innovative pump fittings has never been more evident. According to a recent report by the Global Pump Market Insights, the pump fittings segment is projected to reach a valuation of $30 billion by 2025, driven by advancements in technology and the growing demand for efficient fluid management systems across various sectors. As industries increasingly prioritize sustainability and efficiency, the integration of smart materials and pioneering designs into pump fittings has the potential to enhance performance, reduce maintenance costs, and prolong equipment life. This blog will explore the transformative impact of these innovations, providing essential tips for industry professionals looking to leverage the latest advancements in pump fittings to optimize their operations and remain competitive in a rapidly changing market.

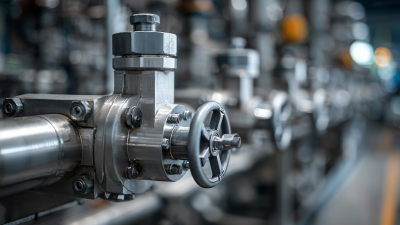

Innovative pump fitting technologies are at the forefront of transforming industrial applications across various sectors. One significant trend is the integration of smart technology into pump fittings, enabling real-time monitoring and data collection. This advancement allows industries to optimize performance and predictive maintenance, significantly reducing downtime and operational costs. For instance, sensors embedded within fittings can detect pressure fluctuations and potential leaks, alerting operators before problems escalate.

Another current trend is the shift towards sustainable and eco-friendly materials in the production of pump fittings. Many companies are now prioritizing materials that minimize environmental impact while maintaining high durability and performance standards. These innovations not only contribute to a cleaner environment but also align with the growing demand for sustainable practices in industries ranging from manufacturing to agriculture. As businesses increasingly adopt these advanced fittings, they not only enhance efficiency but also foster a more responsible and sustainable industrial landscape.

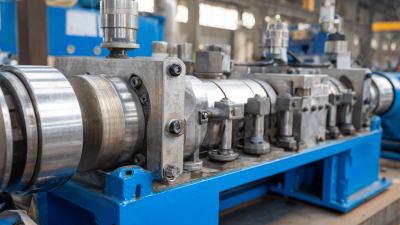

The landscape of industrial applications is witnessing a remarkable transformation, driven by innovative pump fittings engineered with advanced materials. These enhancements not only boost the performance of pumping systems but also ensure their long-term durability. Materials like high-performance polymers and composites are now commonplace in pump fitting designs, offering excellent resistance to corrosion, temperature fluctuations, and wear. This shift is pivotal, as industries increasingly rely on efficient and robust equipment to maximize productivity while minimizing downtime.

When considering upgrades or new installations, it’s essential to choose pump fittings crafted from these durable materials. One tip for those in the industry is to conduct a thorough assessment of the specific environmental conditions your pumps will face. Understanding factors like fluid abrasiveness and temperature ranges can inform better choices in material selection. Additionally, ensure that your fittings are compatible with existing systems to avoid future complications.

Another key innovation is the development of fittings with improved geometries, which reduce turbulence and enhance flow rates. This not only increases efficiency but can also lead to significant energy savings. As you evaluate options, consult with manufacturers about the engineering behind these designs, as it can vastly influence overall system performance. Embracing these advancements will not only extend the lifespan of your equipment but also position your operations for future growth.

The integration of the Internet of Things (IoT) into pump fittings is revolutionizing industrial applications by enhancing performance and optimizing operations. Smart pump fittings equipped with sensors and connectivity capabilities enable real-time monitoring of fluid dynamics, pressure, and flow rates. This immediate access to data allows for proactive maintenance, minimizing downtime and reducing operational costs. Industries can respond to changing conditions swiftly, ensuring that systems run efficiently and preventing costly failures.

Moreover, IoT-enabled pump fittings facilitate remote management and control. Operators can oversee multiple systems from their devices, adjusting parameters on-the-go to meet fluctuating demands. The data gathered not only aids in optimizing current processes but also contributes to predictive analytics, giving businesses insights to improve future operations. As industries continue to adopt these smart technologies, we can expect significant advancements in sustainability, energy efficiency, and overall productivity, setting a new standard for performance in industrial applications.

| Parameter | Description | Benefits | IoT Integration |

|---|---|---|---|

| Material Used | Corrosion-resistant alloys and composites | Increased durability and lower maintenance costs | Real-time monitoring of wear and tear |

| Flow Rate Regulation | Automated flow adjustments based on demand | Optimized energy consumption | Remote control and adjustments via mobile apps |

| Smart Sensors | Embedded sensors for pressure and temperature monitoring | Enhanced safety and performance tracking | Data analytics for predictive maintenance |

| Energy Efficiency | Integration of energy-efficient designs | Lower operational costs | Monitoring energy consumption remotely |

| Compatibility | Designed for various pumping systems | Flexibility for diverse industrial applications | Easier integration with existing IoT infrastructures |

The design of pump fittings has evolved significantly in recent years, with sustainability now at the forefront of innovation in the industrial sector. According to a report by the Global Industry Analysts, the global market for industrial pumps is expected to reach $95 billion by 2026, reflecting a growing emphasis on characterizing environmental impact. Sustainable pump fitting designs not only prioritize efficiency but also incorporate eco-friendly materials. The use of advanced polymers and composites reduces the carbon footprint during production while enhancing performance longevity.

Furthermore, recent studies indicate that environmentally conscious pump fittings can decrease energy consumption by up to 30% compared to traditional metal fittings. This reduction contributes significantly to lower greenhouse gas emissions and operational costs for industries. As organizations pursue sustainability initiatives, the adoption of green technologies, including recyclable and bio-based materials in pump fittings, can enhance corporate responsibility efforts while meeting regulatory standards. The integration of smart technology in fittings aids in monitoring performance, further minimizing waste and inefficiencies in industrial processes.

The continuous evolution of industrial applications demands solutions that not only meet current operational challenges but also anticipate future needs. Adaptive pump fittings represent a significant advancement in this arena, enabling industries to future-proof their processes. According to a recent market report, the global smart pumps market is projected to reach $8.6 billion by 2025, underscoring the growing trend towards integrating intelligent technologies in fluid management.

These innovative fittings enhance operational adaptability by utilizing AI-driven technologies, which streamline installation and maintenance, resulting in reduced downtime and increased efficiency. For instance, enterprises that have embraced such adaptive solutions report a 20% improvement in efficiency and up to 30% reduction in operational costs. This transformation is akin to developments seen in other sectors; AI applications in telecommunications have achieved similar efficiencies, highlighting a broader industrial shift towards data-driven adaptability.

Moreover, just as cities are restructuring through advanced flood protection and urban design techniques to withstand climate challenges, industrial sectors are leveraging adaptive pump fitting solutions to enhance resilience against operational disruptions. As industries face the pressing need for sustainability and efficiency, the integration of these innovative fittings will be crucial for maintaining competitiveness in a rapidly evolving landscape.

This chart illustrates the importance levels of various features of innovative pump fittings in industrial applications. Adapting to changing demands is crucial for future-proofing industrial solutions.