MENUMENU

Steam relief valves are critical components in maintaining safety and operational efficiency in industrial systems that utilize steam as a medium for energy transfer and processing. According to a report by the American Society of Mechanical Engineers (ASME), improper functioning of steam relief valves can lead to catastrophic failures, resulting in significant financial losses and even injury to personnel. The International Association for the Properties of Water and Steam (IAPWS) emphasizes that these valves are designed to prevent excessive pressure build-up in steam systems, which can otherwise lead to explosive incidents.

Moreover, a study by the National Board of Boiler and Pressure Vessel Inspectors indicates that over 60% of pressure-related accidents in industrial settings are attributed to valve failures. This highlights the paramount importance of understanding the functionality, maintenance, and installation of steam relief valves to ensure industrial safety and compliance with regulatory standards.

Steam relief valves are critical components in industrial safety, specifically designed to mitigate the risks associated with pressurized steam systems. By automatically releasing excess pressure, these valves prevent catastrophic failures that could lead to explosions or equipment damage. In environments where steam is utilized for processes such as heating, cleaning, or power generation, the integrity and functionality of relief valves are essential. A malfunctioning valve can result in pressure build-up, endangering personnel and infrastructure alike.

The role of steam relief valves extends beyond mere functionality; they are a crucial line of defense in adhering to safety regulations and standards. Regular maintenance and testing of these valves ensure that they respond appropriately under abnormal pressure conditions. In addition, proper installation and placement are vital, as they must be capable of discharging steam away from personnel and flammable materials. By understanding the significance of steam relief valves and maintaining them diligently, industries can significantly reduce the likelihood of accidents and enhance overall workplace safety.

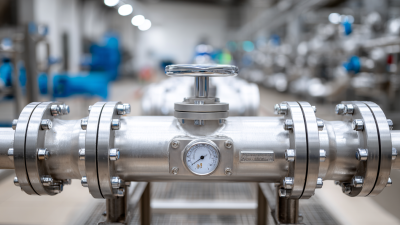

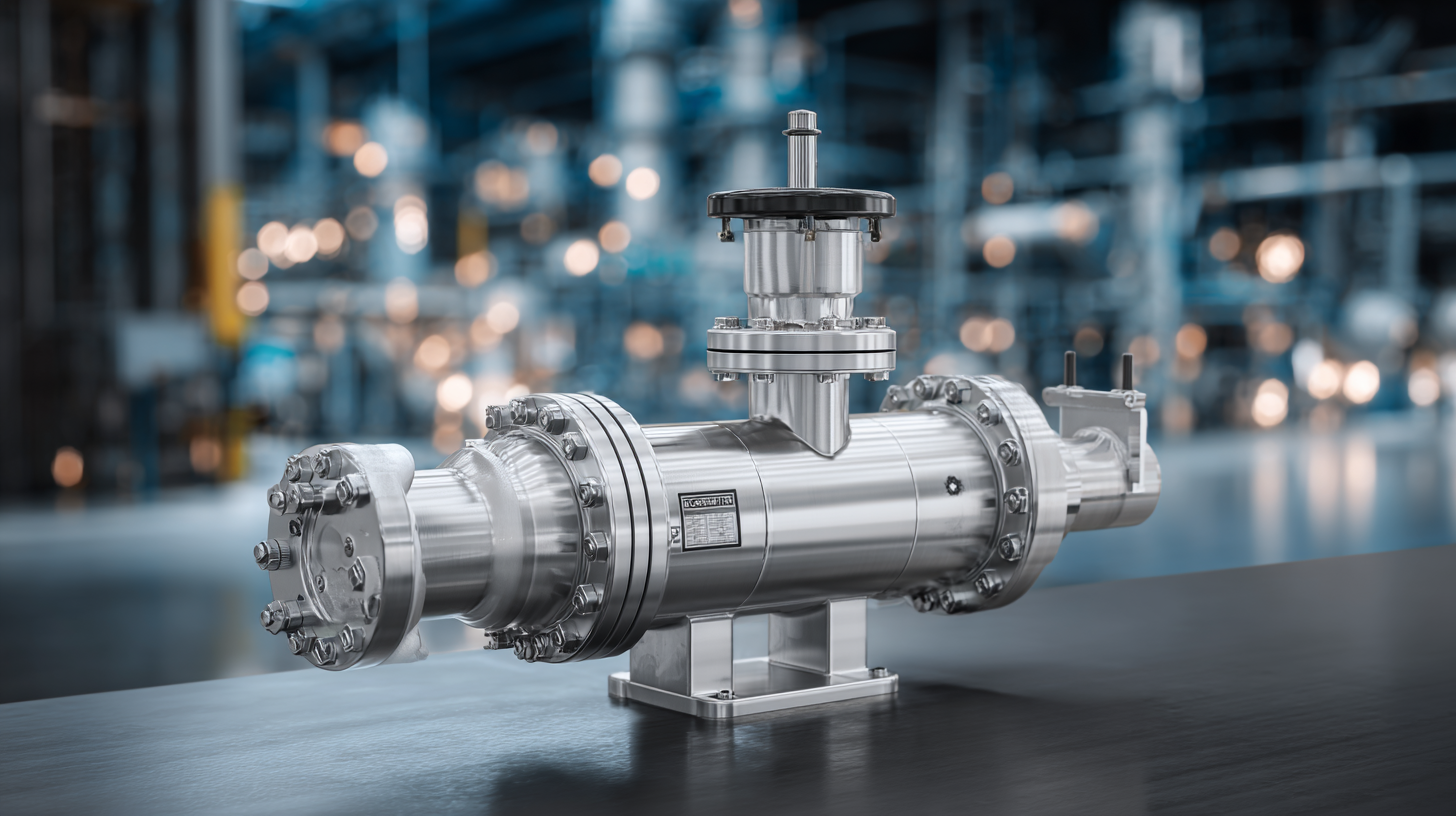

Steam relief valves play a crucial role in maintaining safety within industrial settings, particularly in applications involving high-pressure steam systems. Their primary function is to prevent overpressure conditions that could lead to catastrophic failures. These valves are designed to automatically open when steam pressure exceeds predetermined levels, allowing excess steam to escape safely. This mechanism not only protects equipment but also safeguards personnel from potential injuries due to steam explosions or leaks.

The operation of steam relief valves is based on a straightforward yet effective principle. When the pressure inside a steam system rises to a certain threshold, the valve’s mechanism, often a spring-loaded poppet, pushes the seat off its seal. This action creates an outlet for surplus steam, reducing the pressure to a safe level. Once the pressure normalizes, the spring mechanism allows the valve to reseal, thereby securing the system. Regular maintenance and testing of these valves are essential to ensure their reliability, as any failure in this component can lead to severe consequences, making their function integral to operational safety in industries relying on steam power.

Steam relief valves play a critical role in maintaining safety within industrial settings, particularly in systems that operate under high-pressure conditions. Regulatory standards governing the design, testing, and installation of these valves are established to ensure that they function correctly and effectively prevent overpressure situations. Compliance with standards set by organizations such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) is essential for the protection of both personnel and equipment.

In addition to adhering to national codes, industries must regularly perform inspections and maintenance on steam relief valves to verify their operational integrity. Regulatory bodies typically mandate that these valves are sized and installed according to specific regulations to ensure adequate evacuation of excess steam, thus safeguarding against potential hazards such as explosions or equipment failure. Understanding and implementing these compliance requirements not only enhances workplace safety but also helps organizations avoid legal ramifications and costly shutdowns due to non-compliance.

Steam relief valves are critical components in industrial systems, yet several misconceptions surround their functionality and importance. One common myth is that these valves are merely safety devices and do not play a significant role in overall system efficiency. In reality, steam relief valves not only protect equipment from overpressure but also ensure optimal steam usage by preventing unnecessary system cycling. Properly functioning relief valves contribute to energy savings and improved operational reliability.

Steam relief valves are critical components in industrial systems, yet several misconceptions surround their functionality and importance. One common myth is that these valves are merely safety devices and do not play a significant role in overall system efficiency. In reality, steam relief valves not only protect equipment from overpressure but also ensure optimal steam usage by preventing unnecessary system cycling. Properly functioning relief valves contribute to energy savings and improved operational reliability.

Another misconception is that maintenance of steam relief valves is not a priority. Some operators may believe that these valves do not require regular inspection or testing because they are “set and forget” devices. However, neglecting maintenance can lead to valve failure, potentially resulting in catastrophic consequences. Regular testing and upkeep are essential to ensure that the valves operate correctly and safely, thereby safeguarding both personnel and infrastructure. Understanding these misconceptions is crucial for enhancing industrial safety and ensuring compliance with regulatory standards.

Steam relief valves are critical components in ensuring the safety of industrial operations, particularly in sectors like power generation and oil refining. Proper maintenance and inspection practices for these valves can significantly mitigate the risks associated with steam system failures. Recent studies indicate that implementing predictive maintenance approaches for valve actuators can lead to substantial cost savings and minimize operational disruptions. Power plant operators are increasingly recognizing the value of proactive diagnostics, which can detect potential issues before they escalate into costly outages.

Moreover, best practices in the maintenance of steam relief valves can enhance efficiency and safety across the board. For instance, optimizing steam systems is crucial for reducing energy costs and supporting environmental sustainability. Guidelines established by industry standards, such as ISA-75, underline the importance of regular testing and performance evaluations of control valves to maintain reliability. With incidents of equipment failure leading to safety hazards, it is essential that facilities follow rigorous protocols for inspecting steam relief valves, ensuring they meet operational demands and safety regulations.