MENUMENU

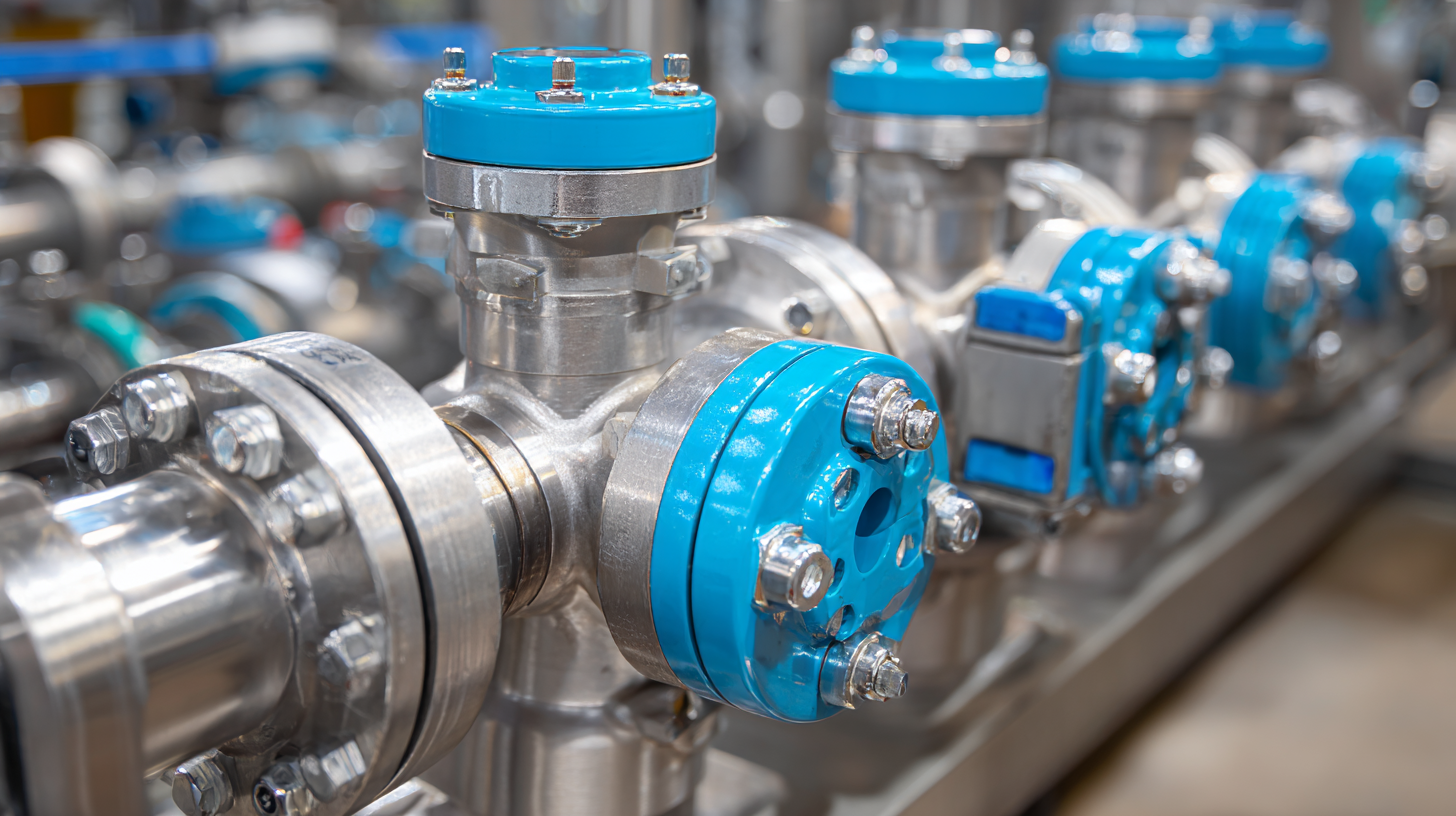

Ball valves are critical components in various industrial applications, offering reliability and efficiency in fluid control. According to a report by Markets and Markets, the global ball valve market is projected to grow from USD 4.52 billion in 2021 to USD 6.77 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is driven by the increasing demand for energy-efficient systems and the rising need for high-performance valves in industries such as oil and gas, water treatment, and chemical manufacturing. Ball valves are favored for their ability to provide tight sealing, lower pressure drop, and quick shut-off capabilities, making them indispensable in operations where precision is paramount. The understanding of ball valves and their critical role in enhancing operational safety and efficiency cannot be underestimated, as they contribute significantly to overall process optimization in a variety of industrial settings.

In the realm of industrial applications, ball valves play a pivotal role in enhancing operational efficiency. With their simple yet effective design, ball valves offer quick shut-off capabilities and minimal pressure drop, making them ideal for a wide range of processes. According to a recent report by MarketsandMarkets, the global ball valve market size is projected to reach USD 12.3 billion by 2025, growing at a CAGR of 5.2%. This growth underscores the increasing reliance on high-performance valves in industries such as oil and gas, water treatment, and chemical manufacturing.

One key advantage of ball valves is their ability to maintain a steady flow rate while reducing the likelihood of leaks. This feature not only helps in conserving valuable resources but also minimizes downtime, which can significantly impact overall production. A case study by Valin Corporation revealed that the integration of modern ball valves in pipeline systems decreased maintenance costs by up to 30%, emphasizing their role in streamlining operations.

**Tip:** When selecting a ball valve, consider factors such as the fluid type, pressure levels, and temperature ranges to ensure optimal performance in your specific application. Additionally, regularly inspect and maintain valves to prevent any operational inefficiencies that could lead to costly repairs.

| Application Area | Ball Valve Type | Material Used | Temperature Range (°C) | Pressure Rating (PSI) | Operational Efficiency (%) |

|---|---|---|---|---|---|

| Oil & Gas | Floating Ball Valve | Carbon Steel | -29 to 232 | 1500 | 90 |

| Water Treatment | Trunnion Ball Valve | Stainless Steel | -10 to 120 | 300 | 85 |

| Chemical Processing | Full Port Ball Valve | PVC | 0 to 60 | 150 | 92 |

| HVAC Systems | V-Ball Valve | Brass | -20 to 150 | 200 | 88 |

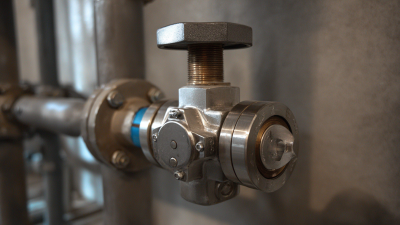

Ball valves play a crucial role in managing flow and pressure within industrial pipelines. Their design incorporates a spherical disc, known as a ball, that can be rotated to allow or restrict fluid flow. When the ball’s hole aligns with the pipeline, fluid flows freely; when it rotates perpendicular to the flow, it effectively seals the passage. This simple yet effective mechanism ensures reliability and efficiency, making ball valves preferred in applications ranging from water treatment to oil and gas industries.

Ball valves play a crucial role in managing flow and pressure within industrial pipelines. Their design incorporates a spherical disc, known as a ball, that can be rotated to allow or restrict fluid flow. When the ball’s hole aligns with the pipeline, fluid flows freely; when it rotates perpendicular to the flow, it effectively seals the passage. This simple yet effective mechanism ensures reliability and efficiency, making ball valves preferred in applications ranging from water treatment to oil and gas industries.

Tip: Regular maintenance of ball valves is essential for optimal performance. Periodically inspect for signs of wear and tear, and ensure that the seals are intact to prevent leakage.

Additionally, ball valves offer advantages such as minimal pressure drop and the ability to handle high flow rates, making them suitable for both high and low-pressure environments. The quick operation of ball valves is particularly beneficial in emergency situations, ensuring that flow can be stopped almost instantaneously without the need for extensive manual intervention.

Tip: Choose the right size and type of ball valve for your specific application to maximize efficiency and ensure durability in operation.

When it comes to industrial applications, the performance of ball valves is critical, and it is evaluated based on stringent industry standards and quality assurance metrics. These standards, such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), provide guidelines on the design, manufacturing processes, and testing methods for ball valves. Compliance with these standards ensures that the valves can withstand the specific pressures, temperatures, and corrosive environments they may encounter in various applications.

Quality assurance metrics play a vital role in assessing the reliability and longevity of ball valves. Factors such as leak testing, material certification, and operational life assessments are crucial for ensuring that the valves maintain optimal performance over time. By implementing rigorous quality control measures, manufacturers can monitor each stage of production, from material selection to final assembly. These practices not only enhance product safety but also boost overall efficiency in industrial processes, making ball valves an essential component in maintaining operational integrity in demanding environments.

Ball valves are crucial components in various industrial applications, particularly in environments that are exposed to harsh conditions. The materials used in manufacturing these valves significantly influence their durability and resistance to corrosion. For instance, stainless steel and brass are commonly preferred for their strength and resistance to oxidizing agents, while high-performance materials like Monel or Hastelloy are chosen for extreme environments where traditional materials might fail.

According to the Valve Manufacturers Association report, the selection of valve materials can reduce maintenance costs by up to 30% in aggressive applications, highlighting the financial benefits of investing in the right materials.

Tip: When selecting a ball valve, consider the specific environmental conditions it will face, including temperature, pressure, and chemical exposure. High temperatures can enhance the corrosion rate, so materials like PTFE should be considered for seals when dealing with heat.

Furthermore, the impact of corrosion resistance cannot be overlooked. Corrosion can lead to valve failure, resulting in costly downtimes and safety hazards. A study by the Institution of Mechanical Engineers indicates that improperly selected valve materials account for more than 25% of failures in processing plants. Hence, choosing materials that are specifically engineered for corrosion resistance, such as PVC or specialized alloys, is essential in extending the lifespan of ball valves and ensuring reliable operations in industrial setups.

Tip: Regularly inspect and maintain ball valves to detect early signs of wear or corrosion. This proactive approach can enhance the longevity and reliability of your valve systems, ultimately protecting your investment.

In today's industrial landscape, the implementation of ball valves is more than just a matter of efficiency; it's a strategic investment that offers significant long-term savings. Ball valves are known for their durability and reliability, which translates into reduced maintenance costs over time. Unlike other valve types, ball valves are less prone to wear and tear, which decreases the frequency of replacements and repairs. This characteristic is particularly beneficial in high-frequency operations where downtime can lead to substantial financial losses.

Furthermore, the cost-benefit analysis of integrating ball valves into industrial processes reveals that their superior flow control can lead to increased energy efficiency. By optimizing the flow of fluids, businesses can minimize energy consumption, resulting in lower operational costs. Additionally, the quick operation of ball valves ensures that processes can be adjusted swiftly, further enhancing productivity and reducing waste. Ultimately, investing in ball valves may involve a higher upfront cost, but the long-term financial advantages and operational efficiencies they provide make them a wise choice for industrial applications.