MENUMENU

In today’s industrial landscape, the role of high pressure valves is critical for ensuring operational efficiency and safety across various applications. According to a report by MarketsandMarkets, the global high pressure valve market is projected to reach USD 7.3 billion by 2025, with a substantial compound annual growth rate (CAGR) of 5.5%. These valves are essential components in industries such as oil and gas, chemical processing, and power generation, where they regulate the flow of fluids under high pressure conditions. Their ability to withstand extreme environments not only safeguards equipment but also optimizes performance by preventing leaks and potential hazards. Understanding the importance of high pressure valves is therefore vital for industry professionals, as they play a pivotal role in maintaining system integrity and enhancing the longevity of industrial operations.

High pressure valves are critical components in various industrial applications, fundamentally influencing operational efficiency and safety. In environments where fluids are transported, controlled, or processed at high pressures, these valves must maintain integrity under extreme conditions. Their ability to withstand high temperatures and pressures ensures that they prevent leaks and failures that could lead to hazardous situations, thereby protecting both personnel and equipment.

Moreover, high pressure valves are instrumental in optimizing processes in industries such as oil and gas, chemical manufacturing, and power generation. They help regulate flow rates, maintain pressure levels, and control temperature fluctuations, which are vital for maintaining product quality and operational reliability. The strategic implementation of these valves not only promotes efficiency but also contributes to regulatory compliance and risk management, highlighting their indispensable role in modern industrial settings.

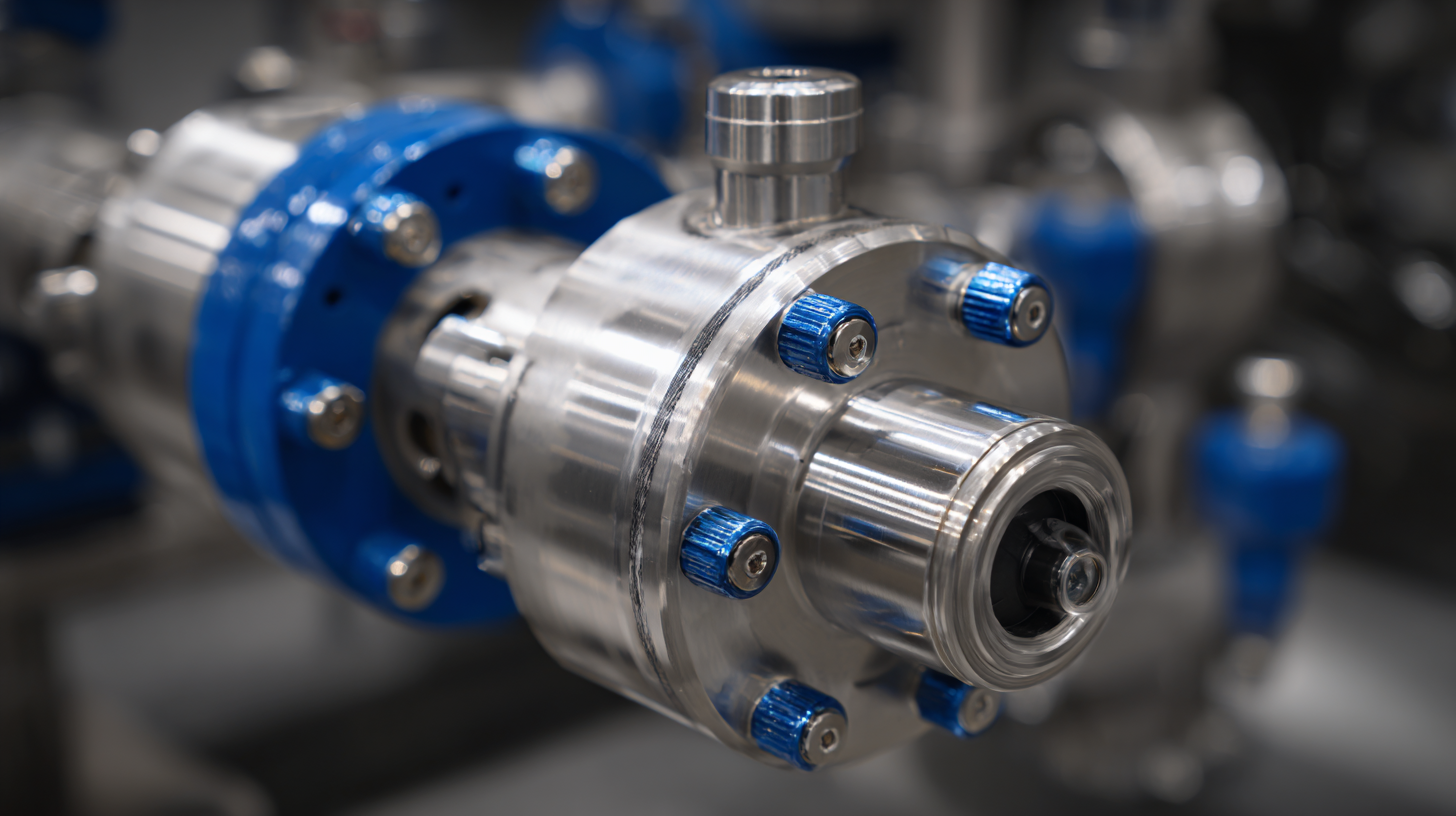

High pressure valves play a critical role in various industrial applications, particularly in managing the flow of fluids and gases under elevated pressures. Their design must accommodate extreme conditions while ensuring safety and reliability. One of the key features that define the performance of high-pressure valves is their construction materials. Typically manufactured from robust materials like stainless steel or alloyed metals, these valves are engineered to withstand corrosion and physical stress, which is essential for their longevity and durability in demanding environments.

Another important aspect is the sealing mechanism employed in high-pressure valves. Effective sealing is crucial to prevent leaks that can lead to operational inefficiencies or hazardous situations. Various sealing technologies, such as valve seats made from elastomers or PTFE, enhance the capability of these valves to maintain integrity under pressure fluctuations. Additionally, pressure ratings and temperature tolerances significantly impact their performance; selecting valves that match the specific requirements of the application is vital for optimal operation. By understanding these key features, industries can make informed decisions when selecting high-pressure valves to ensure efficiency, safety, and performance in their processes.

| Feature | Description | Applications | Material | Pressure Rating (psi) |

|---|---|---|---|---|

| Pressure Control | Maintains desired pressure level in pipelines | Oil & Gas, Chemical Processing | Stainless Steel, Carbon Steel | 5000 |

| Flow Control | Regulates flow rates within systems | Power Generation, Water Treatment | Bronze, PVC | 3000 |

| Durability | Resistant to wear and tear, ensuring long-lasting performance | Mining, Manufacturing | Alloy Steel, High-Density Polyethylene | 4000 |

| Safety Features | Equipped with emergency shut-off and pressure relief systems | Petrochemical, Pharmaceuticals | Titanium, Teflon | 6000 |

| Ease of Maintenance | Designed for quick and easy inspections and service | Food Processing, HVAC | PP, PVDF | 2500 |

High pressure valves play a crucial role in various industrial applications, providing efficient control and regulation of fluid flow under extreme conditions. These valves are particularly vital in sectors such as oil and gas, chemical processing, and power generation. According to a report by Research And Markets, the global high pressure valve market is expected to reach approximately $8.4 billion by 2027, driven by increased demand for safe and efficient fluid management systems (Research And Markets, 2021).

In oil and gas extraction, for instance, high pressure valves are essential for managing the flow of crude oil and gas from the wellhead to processing facilities, where pressures can exceed 15,000 psi. Properly functioning valves ensure safety and reduce the risk of catastrophic failures. In chemical processing, they help in controlling reactions that occur at elevated pressures and temperatures, enhancing process efficiency and product quality.

**Tips:** When selecting high pressure valves for your application, consider their material compatibility with the fluids being processed and ensure they are certified for the specific pressures and temperatures involved. Regular maintenance checks are also critical to prevent leaks and ensure reliability. Another tip is to invest in valves equipped with advanced actuator technologies that improve responsiveness and reduce downtime.

High pressure valves play a crucial role in various industrial applications, from oil and gas to manufacturing processes. To ensure their longevity and optimal performance, regular maintenance is essential. According to industry reports, valves should be inspected for wear and tear, corrosion, and proper installation. For instance, maintaining the seals and packing can prevent leakage, which, as indicated by fluid technology standards, can significantly enhance the reliability and efficiency of the entire system.

Moreover, lubricating the moving parts and ensuring that all joints are tight can prevent premature failure. It is estimated that improper maintenance can lead to a reduction of valve life by up to 40%. Gathering data suggests that timely maintenance practices can not only enhance the functionality of high pressure valves but also contribute to overall cost savings in industrial operations. Thus, companies that prioritize structured maintenance schedules are likely to see improved operational efficiency and reduced downtime.

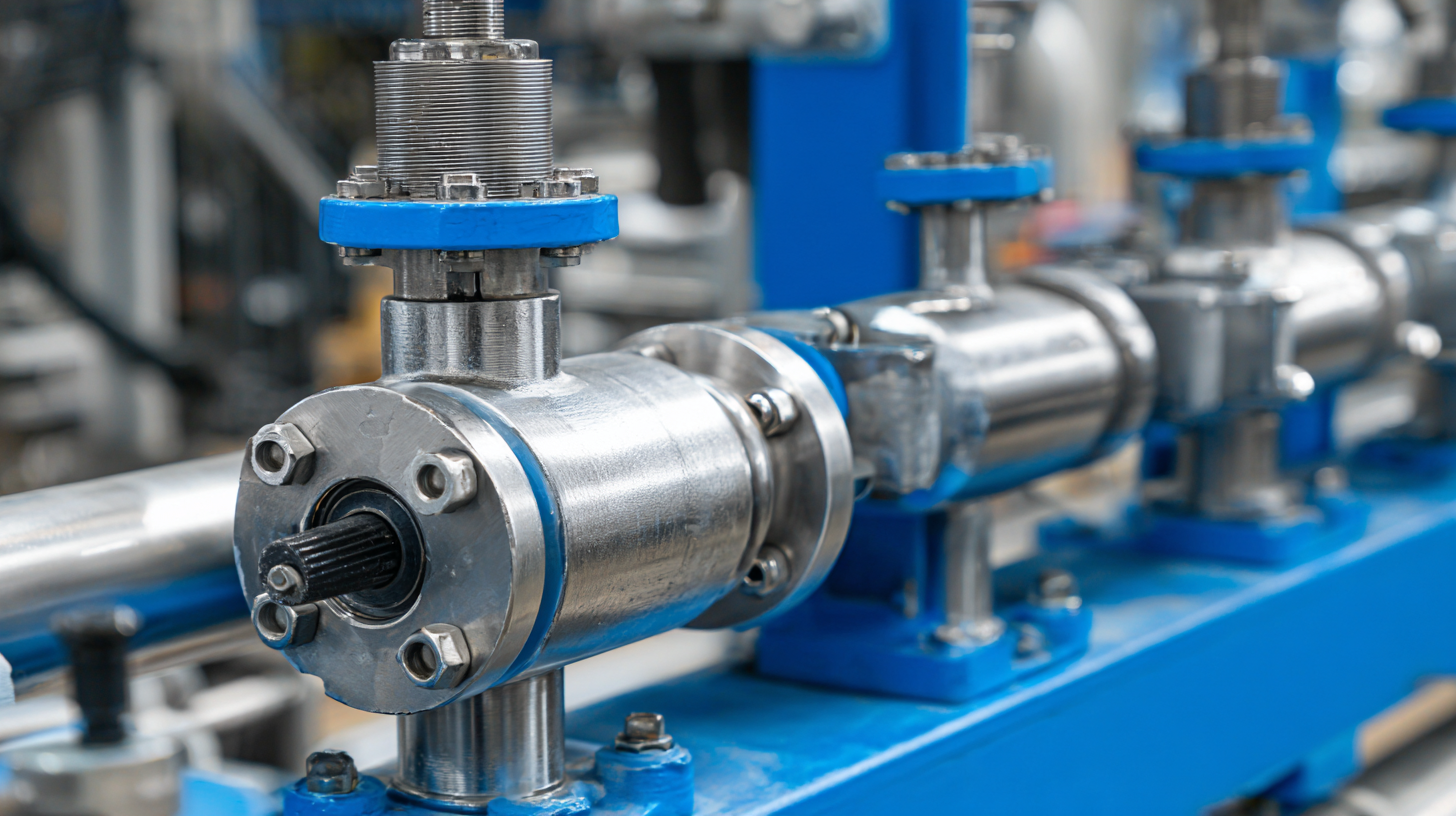

When selecting a high pressure valve for industrial applications, the specific requirements of the system must be carefully considered. High pressure valves come in various types, including globe, gate, ball, and check valves, each offering distinct advantages depending on the application. For example, globe valves are ideal for throttling services due to their design that allows for precise flow control, while ball valves excel in applications requiring quick shut-off capabilities.

It is also crucial to consider the materials of construction for the valve, as they impact performance, durability, and suitability for particular media. For applications involving corrosive substances, a valve made from stainless steel or specialized alloys may be necessary to ensure longevity and prevent failures. Additionally, factors such as pressure ratings, temperature ranges, and compliance with safety standards should guide the selection process. By aligning the valve choice with the specific demands of the application, one can enhance operational efficiency and minimize maintenance costs.