MENUMENU

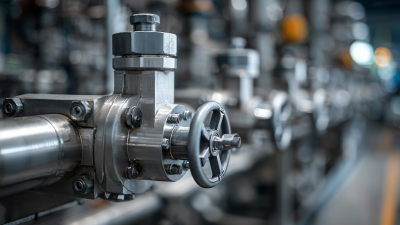

In the realm of industrial safety systems, the significance of high pressure relief valves cannot be overstated. These critical components serve as the first line of defense against the dangers associated with excessive pressure within various systems, ensuring that operations remain safe and efficient. The improper management of pressure can lead to catastrophic failures, equipment damage, or even severe injuries, which underscores the necessity for high pressure relief valves in any industrial application.

Understanding how high pressure relief valves function and their vital role in maintaining safe operational limits is crucial for engineers and safety personnel alike. By effectively releasing excess pressure, these valves help to prevent potential hazards that could arise from equipment overload or system failure. This article will explore the "Top 10" reasons why high pressure relief valves are indispensable in industrial contexts, highlighting their importance not only in safeguarding machinery but also in protecting the well-being of workers and the environment. Through this exploration, we aim to emphasize the critical role that these valves play in enhancing safety protocols and ensuring compliance with regulatory standards.

High pressure relief valves play a crucial role in maintaining safety within industrial applications by preventing the potentially catastrophic consequences of over-pressurization. These valves are designed to automatically release excess pressure from a system, thereby minimizing the risks associated with pressure buildup. By doing so, they protect equipment, machinery, and personnel from damage and injury. The immediate response of these valves to high-pressure conditions ensures that operations can continue safely, which is essential in environments where machinery operates under high stress.

In addition to their protective function, high pressure relief valves contribute to the overall efficiency of industrial processes. By managing pressure levels, these valves help to maintain optimal operating conditions, reducing the likelihood of costly downtime and equipment failures. Furthermore, their reliable operation helps in compliance with safety regulations, safeguarding not only the physical assets of a facility but also the well-being of its workers. Incorporating high pressure relief valves into industrial systems is not just a regulatory requirement; it is a strategic decision that supports sustained operational integrity and enhances safety culture within an organization.

High pressure relief valves (PRVs) play a crucial role in safeguarding industrial environments by mitigating various risks associated with pressure buildup. One of the top risks addressed by effective pressure relief systems is the potential for catastrophic equipment failure. According to the American Petroleum Institute, nearly 70% of industrial incidents stem from inadequate pressure management, which can lead to explosions and fires. By ensuring that pressure does not exceed safe operational limits, PRVs help protect both personnel and equipment from devastating failures.

Another significant risk is the hazard of toxin release. In industries handling hazardous materials, pressure buildup can lead to leaks and spills, posing severe health and environmental threats. A report from the Chemical Safety Board highlighted that over 40% of major chemical accidents could have been prevented with the proper implementation of pressure relief systems. By automatically relieving excess pressure, these valves help contain harmful substances and maintain safe working conditions, ultimately reducing the likelihood of accidents.

Additionally, PRVs play a vital role in operational efficiency. By preventing unnecessary pressure fluctuations, they enhance the performance of industrial processes. For instance, manufacturers that have integrated effective pressure relief systems have reported up to a 30% increase in operational uptime. This not only safeguards personnel and equipment but also contributes to improved productivity and cost savings in highly regulated industries.

When selecting a high pressure relief valve for industrial operations, understanding the specific requirements of your system is crucial. According to a report by the American Society of Mechanical Engineers (ASME), approximately 15% of all industrial accidents are attributed to pressure-related failures, making the choice of the right valve vital for overall safety. Factors such as the type of fluid, operating temperature, and pressure ratings should be carefully assessed. For example, valves made from stainless steel are often preferred in corrosive environments due to their durability and resistance to chemical degradation.

Moreover, it’s essential to consider the valve's capacity and response time. The National Board of Boiler and Pressure Vessel Inspectors emphasizes that a relief valve must relieve pressure quickly enough to prevent catastrophic failures, which can sometimes occur within seconds. Ideally, a valve should be selected that not only meets the maximum allowable working pressure (MAWP) of the system but also has a capacity margin calculated based on process conditions. Utilizing industry standards and guidelines, such as those from the API (American Petroleum Institute), can aid operators in making informed choices that enhance both efficiency and safety in their operations.

This chart illustrates the distribution of high pressure relief valve failures due to different causes in industrial operations. Understanding these factors can help in selecting the right valve for enhanced safety.

High pressure relief valves play a crucial role in maintaining industrial safety systems, particularly in high-stakes environments such as the pharmaceutical industry. With the market for low-temperature valves projected to exceed $577 million by 2024 and expected to grow at a compound annual growth rate of 7.5% through 2034, the demand for reliable and efficient valves is evident. This growth is largely fueled by the increased usage of specialty gases in drug and vaccine applications, emphasizing the need for robust safety measures.

To ensure the reliability and safety of these valves, regular maintenance is essential. Implementing a preventive maintenance schedule helps in identifying potential issues early on, thereby avoiding costly downtimes or catastrophic failures. Additionally, training staff on the proper operation and inspection of relief valves can significantly enhance safety protocols.

**Tips**: Always conduct regular inspections to detect any signs of wear or malfunction. Consider investing in high-quality materials to ensure the longevity and effectiveness of the valves. Lastly, maintain thorough documentation of all maintenance activities to track performance over time and aid in compliance with industry regulations.

| Dimension | Description | Best Maintenance Practice | Frequency | Notes |

|---|---|---|---|---|

| Inspection | Regular visual checks for leaks or damage. | Monthly | Monthly | Look for unusual wear or corrosion. |

| Calibration | Ensure that valves operate at the correct pressure settings. | Bi-annual | Every 6 Months | Involves specialized equipment and training. |

| Testing | Functional testing to ensure full operation under pressure. | Annual | Once a Year | Can mimic emergency conditions for better assessment. |

| Cleaning | Remove any debris or buildup that might interfere with function. | Quarterly | Every 3 Months | Use appropriate solvents and methods to avoid damage. |

| Replacement | Replacement of valves that show signs of severe wear or malfunction. | As Required | Upon Inspection Findings | Document all replacements for maintenance records. |

High pressure relief valves are critical components in maintaining the safety and integrity of industrial systems across various sectors. In the oil and gas industry, for example, a major company implemented high pressure relief valves in their drilling operations to mitigate the risks of blowouts. This proactive measure not only enhanced safety protocols but also significantly reduced operational downtime by allowing for controlled pressure release during unexpected surges. The deployment of these valves demonstrated how anticipating pressure fluctuations can avert catastrophic failures.

Similarly, in the chemical manufacturing sector, a facility replaced outdated relief valves with modern, automated systems that provided precise pressure regulation. This allowed for real-time monitoring and immediate response to pressure changes within the system. As a result, incidents of cross-contamination, which were previously a significant concern due to pressure-related failures, were minimized. The successful integration of high pressure relief valves underscored their importance not just for compliance with safety regulations but also for fostering a culture of proactive risk management in complex industrial environments.