MENUMENU

In the realm of fluid management systems, the significance of flow control valves cannot be overstated. These critical components regulate the flow rate and pressure of fluids within a system, ensuring optimal performance and efficiency. As industries increasingly rely on sophisticated fluid control technologies, understanding the function and importance of flow control valves has become essential for engineers and operators alike. Their ability to maintain desired flow conditions facilitates the seamless operation of various applications, from industrial processes to residential plumbing.

Flow control valves come in various designs and types, each tailored to meet specific operational requirements. By analyzing the distinctive characteristics of these valves, professionals can select the most suitable solutions to enhance system efficiency and prevent unnecessary energy expenditure. Furthermore, an in-depth exploration of flow control valves reveals how their proper implementation can mitigate issues such as turbulence, pressure spikes, and flow irregularities, ultimately leading to more reliable and efficient fluid management systems. Thus, this discussion aims to highlight the vital role flow control valves play in the effectiveness and sustainability of fluid handling across numerous sectors.

Flow control valves play a crucial role in optimizing fluid dynamics within management systems, ensuring that the flow of fluids is efficiently regulated. These valves are responsible for adjusting the flow rate, pressure, and direction of fluids, allowing systems to operate at their optimal capacity. By maintaining the desired flow conditions, these valves help to reduce energy consumption and prevent potential damage caused by excessive pressure or flow fluctuations.

In fluid dynamics, the precise control of fluid movement is essential for the effectiveness of various applications, from industrial processes to residential systems. Flow control valves enable engineers to manipulate flow parameters in real-time, ensuring that the system responds appropriately to changing demands. This adaptability not only enhances performance but also improves overall system reliability, leading to longer equipment lifespan and decreased maintenance costs. By integrating advanced flow control valves, organizations can achieve significant improvements in operational efficiency and sustainability.

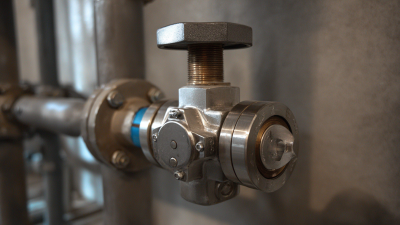

Flow control valves play a crucial role in fluid management systems by regulating the flow rate and pressure of liquids and gases. There are several types of flow control valves, each designed with unique benefits that cater to various applications. For example, needle valves provide precise flow regulation, making them ideal for applications requiring fine control, such as in laboratory settings or intricate machinery. Their design allows for minimal fluid turbulence, ensuring accuracy in measurements and operations.

Another popular type is the ball valve, known for its robust design and quick on/off functionality. They are widely used in industrial settings due to their durability and ability to handle high pressure and temperature variations. Ball valves offer excellent sealing capabilities, preventing leaks and ensuring system integrity. Lastly, flow restrictors, which limit the flow rate in a system without the need for complex adjustments, are perfect for simplifying control in low-pressure applications. Each type of flow control valve brings distinct advantages, making them essential components for optimizing fluid management systems across various industries.

Flow control valves play a crucial role in various industries by regulating the flow of fluids in systems, thereby ensuring efficiency and safety. In the oil and gas sector, these valves manage the flow of raw materials and refined products, allowing for precise control during extraction, transportation, and processing. Their ability to adjust flow rates helps prevent leaks and overpressurization, which can lead to environmental hazards and costly accidents.

In the water treatment and distribution industry, flow control valves are vital for maintaining optimal flow rates and pressures. They help in controlling the distribution of water in municipal systems, ensuring that clean water reaches consumers without interruption. Additionally, in manufacturing processes, such as food and beverage production, these valves assist in maintaining the desired flow conditions for ingredients, contributing to product consistency and quality. Overall, their applications span across multiple sectors, highlighting their importance in efficient fluid management systems.

Flow control valves play a crucial role in maintaining optimal performance in fluid management systems, but their implementation often comes with challenges. One common issue is leakage, which can lead to inefficient system operation and increased costs. To address this, it’s essential to select the right type of valve for your specific application, ensuring compatibility with the fluid and operating conditions. Regular maintenance checks can also help identify potential leak points before they escalate into larger issues.

Another challenge is the fluctuation of system pressure, which can create instability in flow rates. This can be mitigated by employing pressure regulators alongside flow control valves, allowing for more consistent control. Additionally, utilizing smart valve technology can provide real-time data monitoring, helping operators adjust settings to maintain desired flow levels.

**Tips:** When selecting flow control valves, consider factors such as fluid viscosity, pressure ratings, and temperature ranges. Always consult with a fluid dynamics expert for personalized advice on the best solutions for your system. Moreover, investing in training for your maintenance staff can significantly reduce challenges related to valve upkeep and troubleshooting.

The field of flow control valve technology is undergoing significant advancements, fueled by the increasing demand for efficient fluid management systems across various industries, including pharmaceuticals and automation. In the pharmaceutical sector, the market for diaphragm valves is projected to grow from $123.3 million in 2024 to $284.6 million by 2032, reflecting a robust compound annual growth rate (CAGR) of 11.02%. This growth illustrates the critical role that innovative flow control solutions play in meeting the rigorous demands of modern manufacturing processes.

Looking ahead, innovations in flow control valve technology are anticipated to enhance the operational efficiencies of fluid management systems. As industries gear up for smart manufacturing, the integration of intelligent algorithms and advanced materials in valve design will likely drive performance and reliability. For example, the rapid evolution of computing power, with China's smart computing scale expected to reach 1,037.3 EFLOPS by 2025, underscores the importance of automation and real-time monitoring capabilities in optimizing flow control processes. These developments are essential for addressing the growing complexity of production environments and ensuring sustainability in fluid management systems.