MENUMENU

In the realm of fluid dynamics and hydraulic systems, the flow control valve plays an essential role in regulating the flow rate of liquids and gases. Understanding its types and applications can significantly enhance system performance and efficiency. According to Dr. Jane Miller, a prominent expert in fluid management technologies, "The precise control of flow using a flow control valve not only optimizes system operations but also ensures safety and reliability across various industrial applications."

As industries continue to innovate and automate processes, the importance of flow control valves has surged. These components come in various designs, each tailored to specific applications, allowing operators to achieve the desired flow characteristics. Whether it’s in water treatment facilities, manufacturing plants, or HVAC systems, the effective use of flow control valves determines the sustainability and operational viability of many technologies.

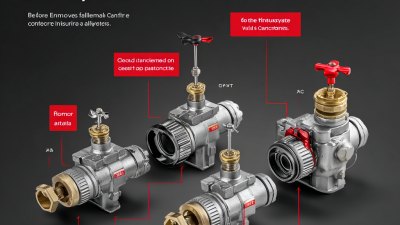

In the following sections, we will delve deeper into the various types of flow control valves—such as globe valves, gate valves, and ball valves—along with their unique functionalities and applications. By gaining a comprehensive understanding of these essential components, engineers and technicians can make informed decisions that enhance system efficiency and reliability.

Flow control valves play a critical role in fluid mechanics by regulating the flow rate and controlling pressure within a system. These valves ensure that fluids move smoothly and efficiently, preventing issues like turbulence and pressure loss. For instance, recent studies have highlighted the dynamics of flow through gate valves, where a clear understanding of flow behavior is paramount to address common problems such as flow separation and pressure drop. This understanding is essential for designing reliable systems in various industrial applications.

In addition to traditional applications, flow control valves are increasingly significant in advanced fields like microfluidics. Trigger valves, for instance, are vital in capillary-driven systems, enabling precise fluid management in channels with abrupt geometric changes. Experimental designs aim to visualize fluid flow under different regimes—laminar, transition, and turbulent—providing insights into how best to manipulate and utilize these flows in practical applications. The ongoing advancements in control valve technology, including efforts to fully linearize their nonlinear characteristics, demonstrate the importance of continuous research and development in enhancing fluid dynamics capabilities.

Flow control valves are critical components in various industrial applications, serving to regulate the flow and pressure of fluids within a system. Understanding the different types of flow control valves is essential for optimizing performance and ensuring compliance with industry standards. According to a report by MarketsandMarkets, the global flow control valve market is projected to grow from USD 13.1 billion in 2023 to USD 18.2 billion by 2028, showcasing the rising importance of these devices across sectors such as oil and gas, water treatment, and manufacturing.

When comparing types of flow control valves, it's essential to consider benchmarks and industry standards. For instance, globe valves are often favored for their throttling capabilities and are widely used in power generation, where precision control is paramount. On the other hand, ball valves are recognized for their quick shut-off features, making them ideal for applications requiring fast operation. According to a study by Research and Markets, the demand for ball valves is expected to increase by over 5% annually, driven by their efficiency and reliability in fluid management systems. Understanding these distinctions allows industries to select the most suitable valve type for their specific needs, enhancing both safety and operational efficiency.

| Type of Flow Control Valve | Applications | Industry Standards | Typical Size Range | Control Method |

|---|---|---|---|---|

| Ball Valve | Water supply, oil & gas | API 608 | 1/2" to 72" | Manual, Pneumatic, Electric |

| Butterfly Valve | HVAC, water treatment | API 609 | 2" to 48" | Manual, Electric |

| Check Valve | Pumping stations, pipelines | API 594 | 1" to 60" | Gravity, Spring-loaded |

| Gate Valve | Oil refineries, power plants | API 600 | 2" to 72" | Manual, Electric, Pneumatic |

| Pressure Relief Valve | Chemical processing, power generation | ASME Section VIII | 1" to 4" | Automatic |

Flow control valves play a crucial role in various industries by regulating the flow rate of liquids and gases within a system. In manufacturing, for example, they are essential for maintaining optimal flow conditions in hydraulic circuits, ensuring that machinery operates smoothly and efficiently. A case study involving a automotive manufacturer revealed that by implementing advanced flow control valves, they reduced energy consumption by 25%, significantly lowering operational costs while enhancing production levels.

In water treatment facilities, flow control valves are vital for managing the distribution of water in different stages of purification. One notable case involved a city’s wastewater treatment plant that utilized flow control valves to optimize the treatment process. By providing consistent flow rates, the facility was able to improve filtration efficiency and reduce the risk of overflow incidents, ultimately leading to better environmental compliance.

Tips: When selecting flow control valves for specific applications, consider the fluid characteristics and operating conditions. Always consult with suppliers to ensure that the valve selected aligns with your project requirements. Regular maintenance of flow control valves can also prevent unforeseen breakdowns, prolonging equipment lifespan and ensuring seamless operations.

The market for flow control valves is witnessing significant growth, particularly in the context of air suspension valves utilized in both two-corner and four-corner air suspension systems. As demand rises across various applications including trucks, racing cars, coaches, and buses, industry analysts predict that this segment will expand considerably by 2033. The insights into regional market dynamics reveal that substantial growth opportunities exist in both developed and emerging markets, driven by innovations in valve technology and the evolving requirements of the automotive sector.

Furthermore, the broader pneumatic components market is projected to exceed $165.7 billion by 2025, with expectations to grow beyond $277.7 billion by 2035. This translates to a robust compound annual growth rate of over 5.3% from 2026 to 2035. As the industry continues to align with high-tech advancements and caters to increasing consumer demands, the flow control valve sector is well-positioned for sustained expansion. With the focus on efficient fluid management solutions, companies are exploring new applications, enhancing product performance, and aligning strategies to capture upcoming market opportunities.

This chart illustrates the projected demand for flow control valves across different applications from 2021 to 2025. The data indicates a growing trend in various sectors, especially in water management and industrial automation, reflecting the increased need for precise flow control solutions.

Flow control valves play a critical role in regulating fluid flow within various systems, and several key factors influence their performance and efficiency. One fundamental aspect is the valve design itself, which encompasses the type of control mechanism, such as proportional, on-off, or modulating functions. Each design offers unique characteristics that affect how accurately and efficiently the valve can manage fluid flow under varying conditions. Additionally, the materials used in manufacturing the valve can significantly impact its durability and responsiveness, particularly in extreme temperatures or corrosive environments.

Another crucial factor influencing flow control valve performance is the operating pressure and temperature range. These parameters dictate the valve's ability to maintain a consistent flow rate and respond to changes in system demands. Furthermore, the application of the flow control valve, whether in hydraulic systems, water treatment facilities, or industrial processes, plays a vital role in determining the optimal valve type and configuration. By considering these key factors, engineers can ensure that flow control valves are effectively integrated into their systems, maximizing efficiency and operational reliability.