MENUMENU

In the realm of fluid dynamics and system efficiency, understanding components like the flow check valve is essential. As industry expert Dr. Sarah Thompson, a leading researcher in hydraulic systems, aptly states, "The effectiveness of a system hinges on its ability to control flow direction and prevent backflow, making flow check valves indispensable." This statement encapsulates the critical role that flow check valves play in ensuring the seamless operation of various systems, from industrial machinery to residential plumbing.

Flow check valves are designed to allow fluid to flow in one direction while preventing reverse flow, thereby protecting equipment and maintaining operational integrity. In applications where backflow could lead to contamination or efficiency losses, the implementation of a high-quality flow check valve is paramount. This article explores the mechanics of flow check valves, their various types, and best practices for integrating them into your system to optimize performance and reliability.

As we navigate through the intricacies of flow check valves, we will delve deeper into their operational principles, the selection criteria for different applications, and the troubleshooting aspects to ensure they work effectively. Understanding these factors will empower professionals to enhance their systems’ resilience and efficiency, ultimately leading to significant benefits in both performance and cost savings.

A flow check valve is a crucial component in various systems, designed to ensure that fluid flows in a unidirectional manner. By preventing backflow, it protects pumps and other equipment from damage caused by reverse currents. The valve operates automatically, utilizing pressure differences to open and close without requiring external power. This characteristic makes it an essential part of plumbing, heating, and industrial systems, where maintaining the correct flow direction is vital for efficiency and safety.

When selecting a flow check valve, consider the type of fluid and the operating pressure within your system. Different materials and designs are suited for liquids, gases, or slurries, making it important to choose the right valve for your specific application.

Tips: Regularly inspect and maintain your flow check valves to avoid any issues that could arise from wear and tear. Ensuring they are free from debris will help maintain optimal performance. Also, be mindful of the installation direction, as incorrect placement can lead to valve failure and system inefficiencies.

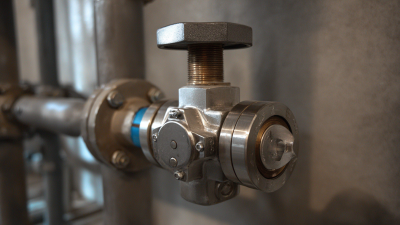

Flow check valves are essential components in various fluid systems, designed to maintain the desired flow direction while preventing backflow. One of the key features of these valves is their simple yet effective mechanism, which typically includes a disc or ball that automatically seals the valve when reverse flow occurs. This functionality ensures that fluids flow only in the intended direction, protecting equipment, preventing contamination, and enhancing system efficiency.

Another important aspect of flow check valves is their versatility in design and application. They come in various types, including inline, swing, and lift check valves, each suited for specific pressures and flow conditions. Key components such as the body, sealing element, and spring (in case of spring-loaded designs) contribute to the valve's performance and reliability. The choice of materials used in the construction, such as stainless steel or PVC, also impacts durability and compatibility with different fluids. Ultimately, understanding these components and features is crucial for selecting the right flow check valve for any system, ensuring optimal operation and longevity.

| Component | Description | Function | Materials Used | Common Applications |

|---|---|---|---|---|

| Body | Outer shell of the valve | Holds internal components and provides structural integrity | Brass, Stainless Steel, PVC | Plumbing, Water Supply |

| Check Mechanism | Device that prevents backflow | Allows flow in one direction while blocking reverse flow | Rubber, Metal, Ceramic | HVAC, Industrial Process |

| Seals | Prevent leakage | Ensure proper sealing when valve is closed | Nitrile, EPDM, Silicone | Agriculture, Water Treatment |

| Spring | Component that assists opening and closing of valve | Controls the movement of the check mechanism | Stainless Steel, Carbon Steel | Fire Protection, Oil & Gas |

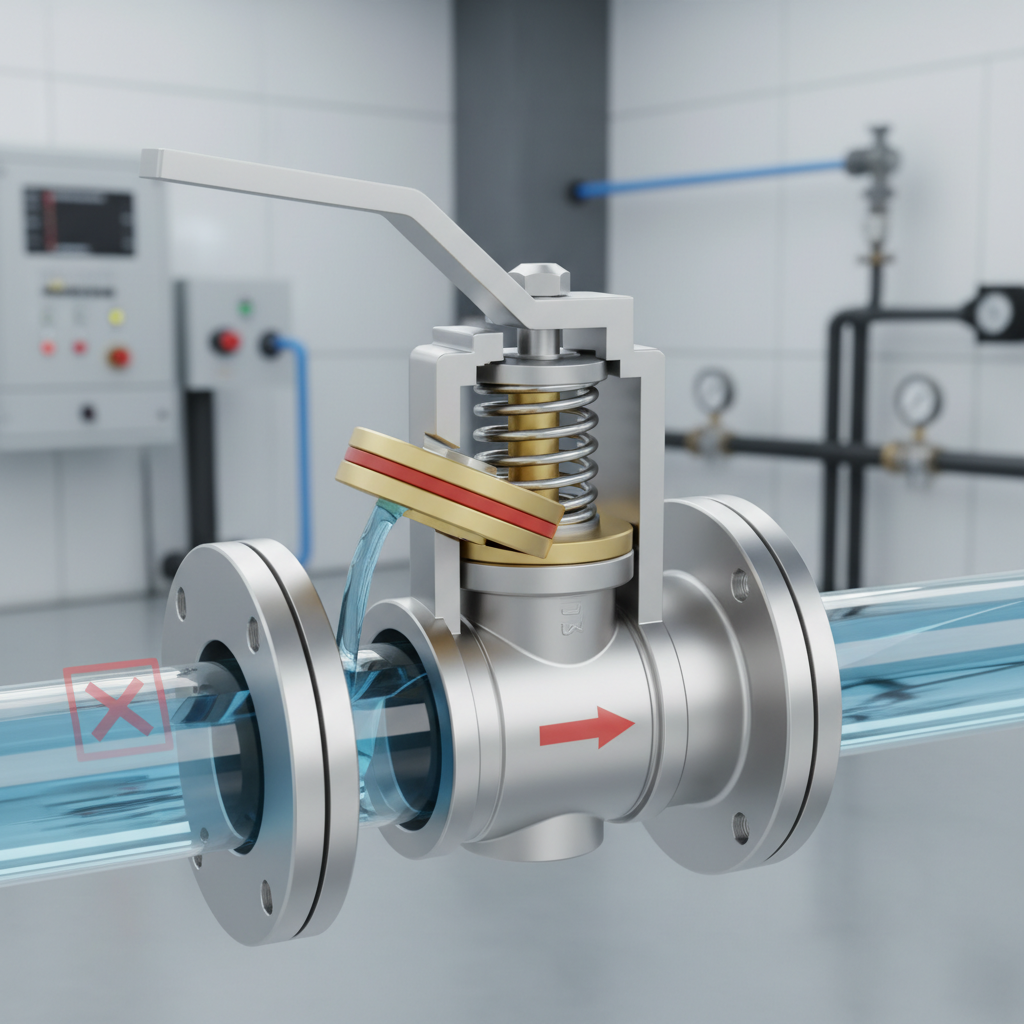

Flow check valves are essential components in fluid systems, designed to ensure that the flow of liquid or gas occurs in a single direction, preventing any backflow that can lead to operational issues. The mechanism behind these valves is relatively simple yet effective. Inside the valve, there is a moving part, often called a disc or ball, which sits against a seat when no fluid flows. This design creates a seal that restricts the backflow of the medium.

When fluid flows in the intended direction, the pressure pushes the disc or ball away from the seat, allowing the flow to pass through. The valve remains open as long as the flow maintains sufficient pressure. In the event of backpressure or a reduction in flow, the disc or ball is forced back onto the seat, effectively closing the valve and preventing reverse flow. This automatic operation is crucial in various applications, from plumbing systems to hydraulic machinery, ensuring efficiency and reliability in fluid management.

Flow check valves play a crucial role in a variety of systems by ensuring the unidirectional flow of liquids and gases. These valves prevent backflow, which can lead to system inefficiencies or damage. In plumbing systems, for instance, flow check valves are used to protect water supply lines from contamination, maintaining the integrity of potable water. They are also integral to heating and cooling systems, where they ensure that water flows in the correct direction, preventing issues such as overheating or freezing.

In industrial applications, flow check valves are essential for maintaining safe and efficient operations. In chemical processing, these valves prevent the reverse flow of hazardous substances, protecting both the equipment and the environment. They are also used in hydraulic systems to maintain pressure and avoid damage caused by backflow. Additionally, in firefighting systems, flow check valves ensure that water flows only in the intended direction, providing reliable water supply when needed. Overall, the application of flow check valves spans a wide range of industries, highlighting their importance in system reliability and safety.

Flow check valves are vital components in both plumbing and industrial setups, offering numerous benefits that enhance system efficiency and reliability. One primary advantage of using these valves is their ability to prevent backflow. By allowing fluid to flow in only one direction, they protect sensitive equipment and piping systems from the potential damage caused by reverse flow, thereby extending the lifespan of infrastructure and minimizing maintenance costs.

Additionally, flow check valves help regulate system pressure, ensuring optimal performance. In industrial applications, maintaining consistent pressure is crucial for processes that require a steady flow of liquids or gases. These valves contribute to stability by automatically closing in case of back pressure, thus safeguarding processes from interruptions and maintaining operational integrity. This not only ensures uninterrupted production but also enhances safety by preventing hazardous spills or leaks, making flow check valves indispensable in modern plumbing and industrial systems.