MENUMENU

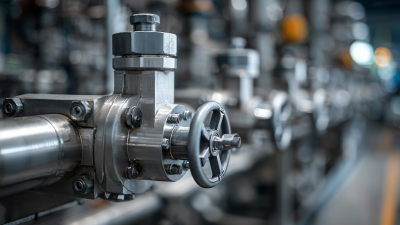

In 2023, the manufacturing industry is witnessing remarkable advancements, particularly in the area of tubing connectors, which are crucial for efficient fluid and gas transfer systems. According to a recent report by MarketsandMarkets, the global tubing connectors market is projected to grow at a CAGR of 6.5%, driven by the increasing demand for automation and improved production methods. These innovations are not only enhancing operational efficiency but also contributing to safety and environmental sustainability. As manufacturers embrace these cutting-edge solutions, the integration of advanced materials and design improvements in tubing connectors is transforming processes across various sectors, from pharmaceuticals to automotive. This blog will explore the seven essential innovations in tubing connectors that are reshaping the landscape of manufacturing in 2023.

The rise of smart tubing connectors is redefining manufacturing paradigms as industries increasingly integrate advanced technologies into their processes. In 2023, manufacturers are witnessing a significant shift towards smart solutions that enhance connectivity and efficiency in production lines.

These innovations facilitate real-time data transmission and automation, allowing for predictive maintenance and optimized workflows. According to a recent industry report, smart tubing connectors can reduce operational costs by up to 30% by minimizing downtime and enhancing system performance.

The convergence of digital technologies and traditional manufacturing is exemplified by the upcoming Munich Shanghai Electronic Production Equipment Show, which aims to showcase cutting-edge innovations that drive the smart manufacturing revolution. This event is set to highlight the growing importance of technology coupling across the entire electric vehicle supply chain, showcasing how smart tubing connectors play a critical role in this transformation.

With predictions suggesting that the smart connector market will expand at a CAGR of over 10% through the next few years, it is clear that these advancements are not just trends but essential components reshaping the industry landscape.

In 2023, the manufacturing industry is witnessing a significant transformation driven by advancements in tubing connector materials. Innovative materials such as high-performance thermoplastics and metal composites are paving the way for enhanced efficiency and durability in manufacturing processes. According to a report by MarketsandMarkets, the global tubing connectors market size is expected to grow from USD 3.6 billion in 2020 to USD 5.1 billion by 2025, with a compound annual growth rate (CAGR) of 7.3%. This growth is largely attributed to the increasing demand for lightweight and corrosion-resistant materials that can withstand the harsh conditions often present in manufacturing environments.

Moreover, the introduction of smart tubing connectors equipped with sensors and IoT capabilities is revolutionizing how manufacturers monitor and manage their production lines. Data from the International Data Corporation (IDC) indicates that the adoption of IoT in manufacturing could increase operational efficiency by up to 30%. These advanced tubing connectors not only reduce downtime through real-time monitoring but also promote sustainability by optimizing resource usage. As companies continue to invest in these innovations, the efficiency and productivity of manufacturing operations are set to reach unprecedented levels, showcasing the immense potential of advanced tubing connector materials.

The modern manufacturing landscape is experiencing a remarkable transformation, largely driven by innovative design features in tubing connectors. These advancements are not merely incremental; they are reshaping how industries approach production processes. Today's tubing connectors integrate features that enhance efficiency, safety, and ease of use, positioning them as indispensable tools in manufacturing operations. For instance, quick-connect designs streamline assembly and disassembly, drastically reducing downtime and labor costs while improving workflow.

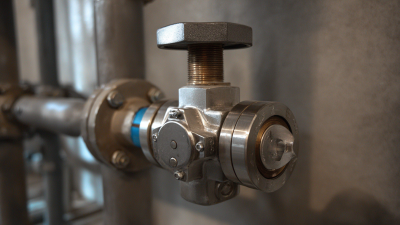

Another noteworthy innovation is the introduction of smart tubing connectors equipped with sensors. These connectors can monitor pressure, flow rates, and temperature in real-time, providing valuable data that enables predictive maintenance and optimization of production lines. Furthermore, the materials used in modern tubing connectors are now designed to withstand extreme conditions, offering durability and resistance to corrosion that extends their lifespan. As these innovations continue to evolve, they will undeniably play a pivotal role in enhancing productivity and sustainability within the manufacturing sector.

In the rapidly evolving manufacturing landscape of 2023, automation has emerged as a pivotal force driving innovation in tubing connector integration. As industries strive for efficiency and precision, automated systems are taking center stage, enabling seamless connections between various components. This shift not only reduces human error but also enhances the speed of production processes, allowing companies to scale up operations without compromising quality.

One significant advancement in tubing connector technology is the introduction of smart connectors equipped with sensors that communicate real-time data. These connectors monitor performance and detect leaks or pressure changes instantly, ensuring proactive maintenance and minimizing downtime. Furthermore, the integration of AI-driven robotics for assembly and maintenance of these connectors streamlines workflows, making the entire manufacturing process more agile and responsive to changing demands. Embracing these automation innovations is not just about keeping pace with technological trends; it's about redefining operational efficiencies and setting new standards in the manufacturing industry.

The manufacturing industry in 2023 has seen a remarkable shift towards sustainability, particularly in tubing connection technology. Recent reports indicate that around 60% of manufacturers are prioritizing eco-friendly innovations, reflecting a growing commitment to reducing waste and improving energy efficiency. One of the most significant advancements is the development of biodegradable tubing connectors. These connectors are made from plant-based materials that decompose within a year, offering a sustainable alternative to traditional plastic options that can take decades to break down.

Moreover, advancements in modular tubing systems are also transforming the sector. According to a study by the International Association of Plastics Industry, modular connectors can reduce material waste by up to 40%. These systems allow manufacturers to easily modify their production lines without the need for complete overhauls, thereby minimizing both resource consumption and carbon emissions. As companies embrace these technologies, they not only meet regulatory pressures but also cater to a growing consumer base that values sustainability, ultimately leading to a more eco-conscious manufacturing environment.