MENUMENU

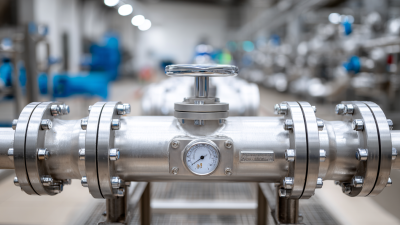

Choosing the right pump fittings is crucial for ensuring optimal performance and longevity in various industrial applications. According to the latest report by the Fluid Control Market Research Institute, the global pump fittings market is projected to reach $7.5 billion by 2025, driven by the increasing demand for efficient fluid management in sectors such as oil and gas, water treatment, and chemical processing. Properly selected pump fittings not only enhance the reliability of pumping systems but also reduce maintenance costs by minimizing leaks and failures.

With a variety of materials, sizes, and configurations available, it can be overwhelming to determine the best options for specific requirements. This guide will provide essential tips and considerations to help you navigate the selection process of pump fittings, ensuring that your applications operate smoothly and effectively.

When selecting pump fittings, understanding the flow rates and pressure ratings is crucial to ensure optimal performance in your applications. Reports from the Hydraulic Institute highlight that improperly sized fittings can cause flow restrictions, leading to decreased efficiency and potential damage to pumps. For instance, a study found that a 10% increase in fitting size can enhance flow rate by up to 15%, thereby reducing energy consumption and wear on pump components.

Furthermore, pressure ratings are equally important. According to the American National Standards Institute (ANSI), matching the pressure rating of fittings with that of the pump is essential to prevent leaks or catastrophic failures. A mismatch can occur if low-rated fittings are used in high-pressure applications, which can result in equipment failure and safety hazards. It's imperative to carefully evaluate the specifications of all components in your pumping system, ensuring that they are compatible with expected flow rates and pressure conditions. Regular assessments and adherence to industry standards can help maintain system reliability and performance.

| Tip Number | Key Consideration | Description | Flow Rate (GPM) | Pressure Rating (PSI) |

|---|---|---|---|---|

| 1 | Material Selection | Choose materials that resist corrosion and environmental factors. | 10-50 | 150-500 |

| 2 | Size Compatibility | Ensure fittings match the pump and piping sizes for optimal flow. | 20-100 | 200-700 |

| 3 | Pressure Drop | Evaluate acceptable pressure drop to prevent system inefficiency. | 5-30 | 100-400 |

| 4 | Connection Type | Select the appropriate connection type (threaded, flanged, etc.). | 15-80 | 150-600 |

| 5 | Maintenance Considerations | Assess maintenance requirements for longevity and performance. | 30-120 | 250-800 |

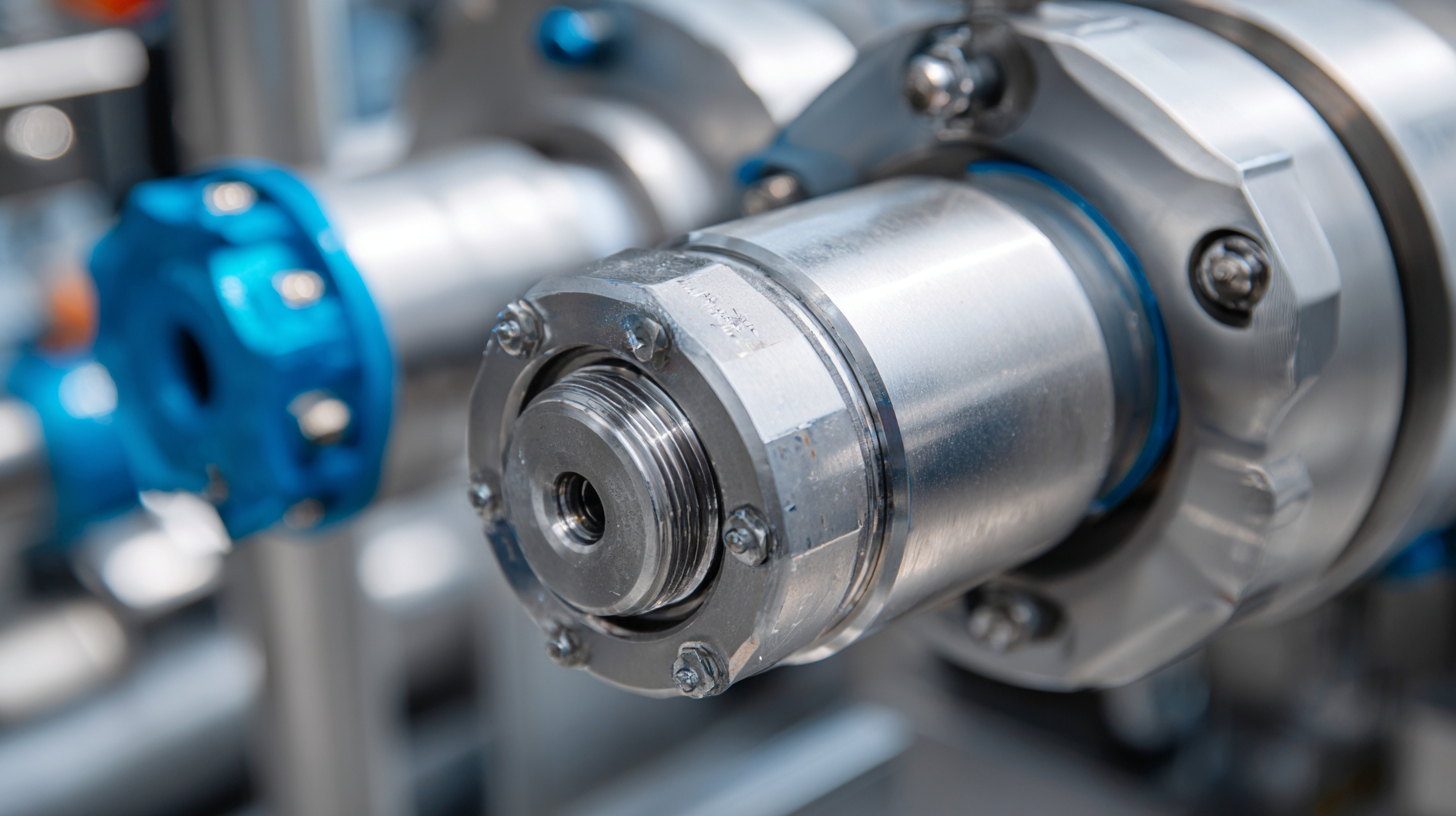

When selecting pump fittings, understanding material compatibility is crucial, especially when dealing with chemical exposure. Different materials react differently when in contact with various chemicals, and using incompatible fittings can lead to severe consequences such as leaks, failures, or contamination of the pumped fluid. It is essential to identify the chemicals being handled and choose fittings made from materials that can resist corrosion or degradation.

For instance, if you are working with acids or aggressive solvents, fittings made from stainless steel or chemical-resistant plastics like PVDF or PTFE may be appropriate choices. On the other hand, for less aggressive fluids, standard polypropylene may suffice. Additionally, reviewing materials’ performance data against the specific chemicals will help ensure the longevity and reliability of the fittings in your application.

Always consult chemical resistance charts and manufacturer guidelines to make informed decisions that prioritize safety and efficiency in your operations.

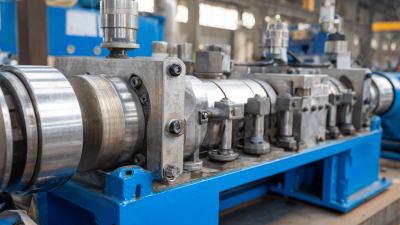

When selecting pump fittings, understanding the importance of size and connection types is crucial for enhancing pump efficiency. Correct sizing ensures that the flow rate is maintained, minimizing the risk of turbulence and pressure loss. Additionally, mismatched connections can lead to leaks or equipment failure, disrupting operations and increasing maintenance costs.

One essential tip is to always refer to the manufacturer’s specifications for the pump and associated fittings. This ensures compatibility and helps to prevent issues related to incorrect sizing. Another key consideration is the materials used for fittings, as they should be suited to the fluid being pumped. This prevents corrosion and prolongs the lifespan of the fittings.

Lastly, consider the type of connection required for your setup. Whether using threaded, flanged, or welded connections, each has its advantages depending on the application. Choosing the right connection type not only enhances performance but also simplifies future maintenance procedures. By keeping these factors in mind, you can achieve a more efficient and reliable pumping system.

When selecting pump fittings, evaluating temperature resistance is crucial for ensuring optimal performance in pump applications. Heat pump systems, particularly those used for residential heating and cooling, must operate efficiently under varying temperature conditions. Research indicates that hybrid ground source heat pump (GSHP) systems significantly enhance energy efficiency and address thermal imbalances often faced in traditional heating methods. For instance, the integration of thermal recovery and intermittent operation strategies can optimize the performance of these systems, enabling them to maintain consistent output even in colder climates.

Furthermore, the effectiveness of a heat pump's operation can be significantly influenced by the design and material of its fittings. Studies have shown that the temperature range in which pump fittings can reliably operate affects the overall efficiency and longevity of the system. In a comprehensive review, it was found that accurate performance monitoring and optimization strategies are essential as heat pumps become increasingly commonplace in residential settings. To maximize ROI, users should ensure that their pump fittings are rated for the specific temperature ranges of their applications, as this can lead to substantial improvements in both energy savings and system durability.

When selecting pump fittings, understanding the relevant industry standards and certifications is crucial for ensuring safety, reliability, and performance. Look for fittings that comply with recognized standards such as the American National Standards Institute (ANSI), the International Organization for Standardization (ISO), and the American Society of Mechanical Engineers (ASME). These organizations provide guidelines that dictate the design, material, and performance specifications necessary for various applications. Compliance with these standards can help in achieving consistent quality and compatibility with existing systems.

Additionally, certifications from organizations like Underwriters Laboratories (UL) or the National Sanitation Foundation (NSF) can offer extra assurance regarding the safety and suitability of pump fittings for specific environments. For example, UL certification signifies that the product has been tested for safety in electrical applications, while NSF certification indicates the fittings meet health and safety standards for potable water. Always ensure that the fittings you choose not only meet performance standards but also carry the required certifications to minimize risks and ensure compliance with local regulations.