MENUMENU

In contemporary fluid management systems, the role of tank valves is critical in ensuring efficiency, safety, and reliability. According to recent industry reports, the global tank valve market is projected to grow at a CAGR of approximately 5.3% from 2023 to 2030, underscoring the increasing demand for advanced fluid control technologies. Tank valves play an essential role in various sectors, including oil and gas, water treatment, and chemical manufacturing, where precision in fluid handling is paramount. The proper functioning of these valves is vital not just for operational efficiency but also for environmental compliance and risk management. With more stringent regulations emerging globally, manufacturers are more inclined to invest in high-quality tank valves that provide enhanced durability and performance. Understanding the intricacies and innovations surrounding tank valves is thus crucial for stakeholders aiming to optimize their fluid management systems in an increasingly competitive landscape.

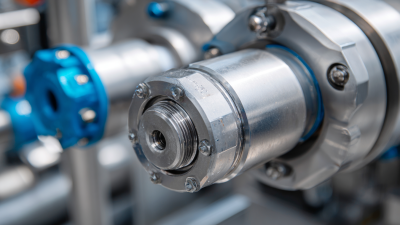

Tank valves play a pivotal role in fluid control systems, ensuring optimal performance and safety in various applications. These valves regulate the flow of liquids and gases, preventing leaks and maintaining the necessary pressure levels within tanks. The critical function of tank valves extends beyond mere fluid management; they help in automating processes, controlling system pressure, and ensuring the integrity of the contained fluids.

**Tips for Selecting Tank Valves**: When choosing tank valves, consider the material compatibility with the fluids being handled to avoid corrosion and leaks. Additionally, ensure the valves are sized correctly for your system’s flow rate requirements. Regular maintenance checks can also help identify wear and prevent costly downtime.

Integrating advanced valve technologies, such as electronic actuators and smart sensors, can further enhance fluid control systems. These technologies provide real-time data and diagnostics, allowing for timely interventions and more efficient management of fluid dynamics. By optimizing valve performance, facilities can improve overall productivity and safety.

In modern fluid management systems, tank valves play a crucial role in ensuring operational efficiency and safety. The global industrial valve market, estimated to reach $121.67 billion by 2024, highlights the growing importance of these components in various industries. A key performance indicator for efficient tank valve operations is the ability to minimize leaks, particularly methane emissions. By effectively sealing and managing these valves, businesses can significantly reduce methane losses, translating to improved profitability from the natural gas supply.

Moreover, advancements in technology, such as SCADA systems, enable real-time monitoring and control of tank valve operations, further enhancing efficiency. These systems contribute to data-driven decision-making, ensuring optimal performance and maintaining safety standards in oil and gas operations. The integration of smart technologies is not just a trend; it's becoming essential for modern fluid management that prioritizes both sustainability and operational excellence. With innovative solutions and continuous improvements, industries can meet their productivity targets while also addressing environmental concerns.

| KPI | Description | Measurement Method | Target Value | Current Value |

|---|---|---|---|---|

| Leak Rate | The amount of fluid leaking from the valve | Measured in liters per hour | < 0.1 L/h | 0.05 L/h |

| Response Time | Time taken to fully open or close the valve | Measured in seconds | < 10 sec | 8 sec |

| Operational Reliability | Percentage of time the valve operates without failure | Calculated as a percentage | > 99% | 98.5% |

| Maintenance Frequency | Average time between maintenance activities | Measured in months | 6 months | 5 months |

| Energy Consumption | Energy used by the valve operation | Measured in kWh | < 50 kWh/month | 45 kWh/month |

Tank valves play a crucial role in modern fluid management systems, especially as industries pivot towards innovative technologies to enhance reliability and safety. Recent advancements highlight the integration of Internet of Things (IoT) solutions in fluid management, facilitating improved monitoring and control of water distribution systems. These technologies enable real-time data collection, significantly reducing non-revenue water and optimizing resource allocation, ensuring that every drop counts in water management.

Moreover, companies focused on safety valve innovation are driving forward the standards for clean energy applications. The emergence of sophisticated safety valves is critical for industries like liquefied natural gas, where the need for reliable and fail-safe mechanisms is paramount. As manufacturers develop new technologies, the emphasis on safety, efficiency, and environmental sustainability ensures that tank valves not only comply with industry regulations but also meet the evolving demands of a cleaner energy landscape.

Tank valves play a crucial role in modern fluid management systems, significantly influencing fluid flow and pressure management. The design of these valves can affect the efficiency and safety of the entire system. For instance, valves with advanced flow control mechanisms, such as adjustable or modulating features, allow for precise regulation of the fluid’s velocity and pressure, ensuring optimal operation. Moreover, innovative materials and streamlined designs help to minimize turbulence, which can lead to pressure drops and inefficient flow dynamics.

Additionally, the placement and configuration of tank valves are vital for maintaining desired fluid characteristics during transport or storage. Valves designed with ergonomic considerations can enhance ease of use and reduce the risk of human error, which is critical in high-stakes environments where fluid integrity is paramount. Consequently, a thoughtful approach to tank valve design is indispensable, not only for maximizing the performance of fluid management systems but also for ensuring safety and reliability in various industrial applications.

In the realm of fluid management systems, tank valves play a pivotal role in ensuring efficiency and safety. According to the American Petroleum Institute (API), compliance with industry standards is crucial for mitigating risks associated with fluid storage and transfer. The API Secondary Containment standard, for instance, mandates that valves must withstand specific pressure levels to prevent leaks and spills, a critical factor in protecting both personnel and the environment.

In the realm of fluid management systems, tank valves play a pivotal role in ensuring efficiency and safety. According to the American Petroleum Institute (API), compliance with industry standards is crucial for mitigating risks associated with fluid storage and transfer. The API Secondary Containment standard, for instance, mandates that valves must withstand specific pressure levels to prevent leaks and spills, a critical factor in protecting both personnel and the environment.

Moreover, the International Organization for Standardization (ISO) sets guidelines that govern the design and testing of tank valves. ISO 9001, which focuses on quality management systems, emphasizes the importance of reliable valve performance in various applications, from petroleum to chemical processing. Research indicates that adherence to these standards not only enhances operational efficacy but also increases the lifespan of valves, reducing the overall cost of maintenance and replacement. As fluid management becomes increasingly complex, understanding and implementing these industry regulations is paramount for organizations aiming to achieve optimal safety and efficiency in their operations.