MENUMENU

As industries continue to innovate and grow, the high pressure relief valve market is poised for significant transformation, with projections indicating an impressive 20 percent growth by 2025. According to a recent report by Market Research Future, the demand for high pressure relief valves is being driven by their critical role in safety and pressure regulation across various sectors, including oil and gas, chemical processing, and water treatment. These valves are essential for preventing equipment failure and ensuring safe operational environments, underscoring their importance in industrial applications.

Additionally, the increasing regulatory standards for safety and efficiency are further propelling market expansion. As we delve deeper into the emerging trends shaping the high pressure relief valve landscape for 2025, it becomes evident that innovation, sustainability, and technological advancements will play pivotal roles in defining the future of this vital component.

Additionally, the increasing regulatory standards for safety and efficiency are further propelling market expansion. As we delve deeper into the emerging trends shaping the high pressure relief valve landscape for 2025, it becomes evident that innovation, sustainability, and technological advancements will play pivotal roles in defining the future of this vital component.

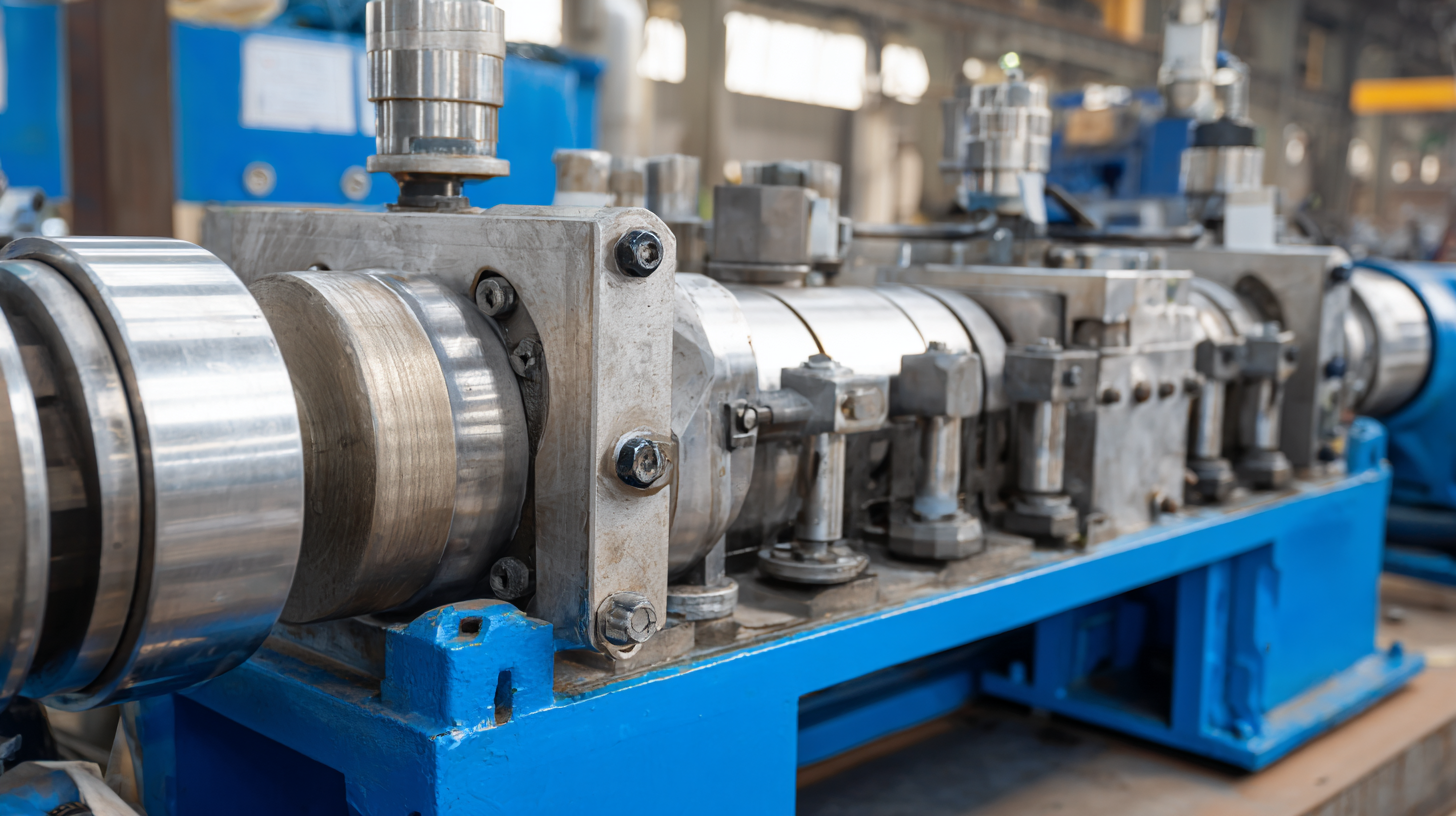

Identifying high-quality high-pressure relief valves (PRVs) in an increasingly competitive market involves understanding the various types available and the specific needs of your application. As the PRV market is expected to grow significantly, reaching values of USD 20.96 billion by 2034, end users must focus on obtaining reliable valves that meet stringent safety standards. Key valve types include spring-loaded, pilot-operated, and dead weight valves, each designed for different pressure thresholds and operational requirements.

When evaluating PRVs, it is essential to consider factors such as material durability, certification compliance, and manufacturer reputation. Ensuring that the valve meets industry standards is crucial not only for performance but also for compliance with safety regulations. Additionally, examining operational efficiency, maintenance requirements, and the availability of parts can help in selecting a valve that minimizes downtime and optimizes system performance. By prioritizing these criteria, buyers can navigate the evolving PRV landscape effectively, ultimately leading to enhanced safety and operational excellence in their applications.

The high-pressure relief valve market is experiencing a significant transformation, projected to achieve a remarkable 20 percent growth by 2025. Key factors driving this growth include the escalating demand for safety in various industries, including oil and gas, chemical manufacturing, and renewable energy. According to industry reports, the global pressure relief valve market was valued at approximately USD 14.45 billion in 2024, with forecasts estimating an increase to around USD 20.96 billion by 2034. This trend highlights the critical role these valves play in maintaining operational safety and mitigating risks associated with high-pressure systems.

In particular, hydrogen energy systems are becoming increasingly pivotal in the shift towards sustainable energy sources, as they require effective pressure relief mechanisms to safely manage hydrogen storage and distribution. This trend not only underscores the importance of regulatory compliance for safety valves but also indicates a rising investment in advanced technologies that optimize performance.

**Tip:** When selecting pressure relief valves, consider the specific requirements of your application, including pressure ratings and temperature ranges, to ensure optimal safety and efficiency. Additionally, staying updated with emerging technologies can enhance your system's reliability and minimize potential failures. Another tip is to actively engage with suppliers on their latest products to choose valves that adhere to the highest safety standards.

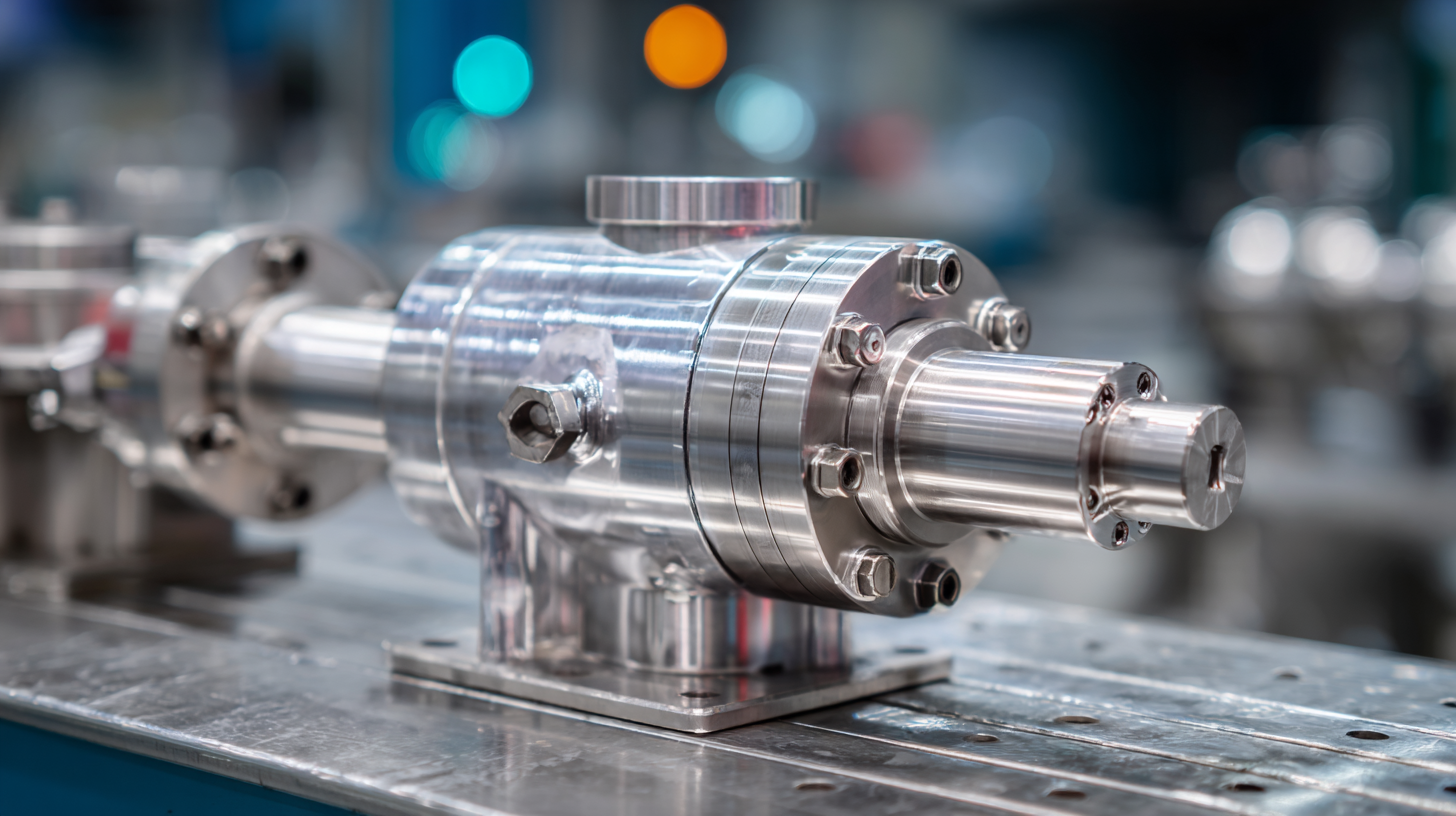

The high pressure relief valve market is set to witness significant transformations driven by innovative technologies, which are increasingly pivotal in enhancing safety and efficiency across various industrial applications. As the industry evolves, reports indicate that the market is projected to grow from approximately $14.99 billion in 2025 to around $20.96 billion by 2034, reflecting a robust growth trajectory. This expansion aligns with broader trends within the safety valve sector, which is estimated to grow from $5.2 billion in 2025 to $11.87 billion by 2035, achieving a compound annual growth rate (CAGR) of 8.6%.

Emerging technologies, including advanced materials and smart monitoring systems, are fundamentally redefining the operational capabilities of high pressure relief valves. These innovations not only enhance reliability and performance but also contribute to compliance with increasingly stringent safety regulations. Additionally, the integration of modern hydraulic systems is essential for maximizing efficiency and functionality, indicating a paradigm shift towards more intelligent and responsive pressure relief solutions. The ongoing commitment to research and development in this field plays a crucial role in addressing the evolving challenges faced by industries, ensuring that high pressure relief valves meet the demands of the future.

| Dimension | 2023 Data | 2025 Projected Data | Growth Rate (%) |

|---|---|---|---|

| Market Size (Million USD) | 500 | 600 | 20 |

| Unit Sales (Thousand Units) | 150 | 180 | 20 |

| Key Applications (% Share) | Oil & Gas (35%) | Oil & Gas (30%) | -5 |

| Average Price (USD) | 3,000 | 3,333 | 11.1 |

When selecting a high pressure relief valve for your application, it’s crucial to consider several key factors to ensure safety and efficiency. According to a report by MarketsandMarkets, the high pressure relief valve market is expected to grow at a remarkable rate of 20% by 2025, driven by increased demand across various industries, including oil and gas, chemical processing, and power generation. The selection process often begins with evaluating the design and specifications of the valve to ensure compatibility with process conditions such as fluid type, pressure, and temperature.

Another important aspect is the valve's set pressure and flow capacity. Industry standards, such as ASME and API guidelines, can help determine the appropriate parameters for safe operation. Additionally, understanding the maintenance requirements and operational characteristics can significantly impact the longevity and reliability of the valve. A comprehensive analysis of these factors will not only enhance operational safety but also reduce the likelihood of costly downtimes, ensuring that your system runs smoothly in an increasingly competitive market.

The competitive landscape for high pressure relief valves in 2025 is shaping up to be more dynamic than ever, driven by technological advancements and an increasing demand for safety and efficiency across various industries. Manufacturers are focusing on innovative designs that enhance performance while ensuring compliance with stricter regulatory standards. This trend is particularly evident as companies invest in research and development to introduce valves that can handle higher pressures and provide more reliable operation under extreme conditions.

In addition to technology, the competitive environment is influenced by strategic partnerships and mergers aimed at expanding product offerings and market reach. Key players are actively seeking collaborations with other industry leaders to leverage complementary strengths, streamline supply chains, and enhance customer service. As the market grows by an estimated 20 percent, understanding these competitive strategies becomes crucial for stakeholders looking to secure their position in the high pressure relief valve market. This evolving landscape ensures that end-users have access to cutting-edge solutions, ultimately supporting safety improvements and operational efficiency across sectors such as oil and gas, petrochemicals, and manufacturing.