MENUMENU

In today’s competitive business landscape, selecting the right hose accessories is crucial for optimizing workflow and ensuring operational efficiency. According to a recent report by the Industrial Hose Manufacturer's Association (IHMA), nearly 60% of businesses experience significant downtime due to improper hose accessory choices. This can lead to increased costs, safety hazards, and unreliable performance. As industries continue to evolve, the demand for high-quality, durable, and efficient hose accessories has never been more pronounced. Understanding the various types of hose fittings, couplings, and adapters available can make a substantial difference in both productivity and profitability. This ultimate guide will provide you with essential tips and insights to effectively choose hose accessories that cater to your specific business needs, in light of the latest industry trends and requirements.

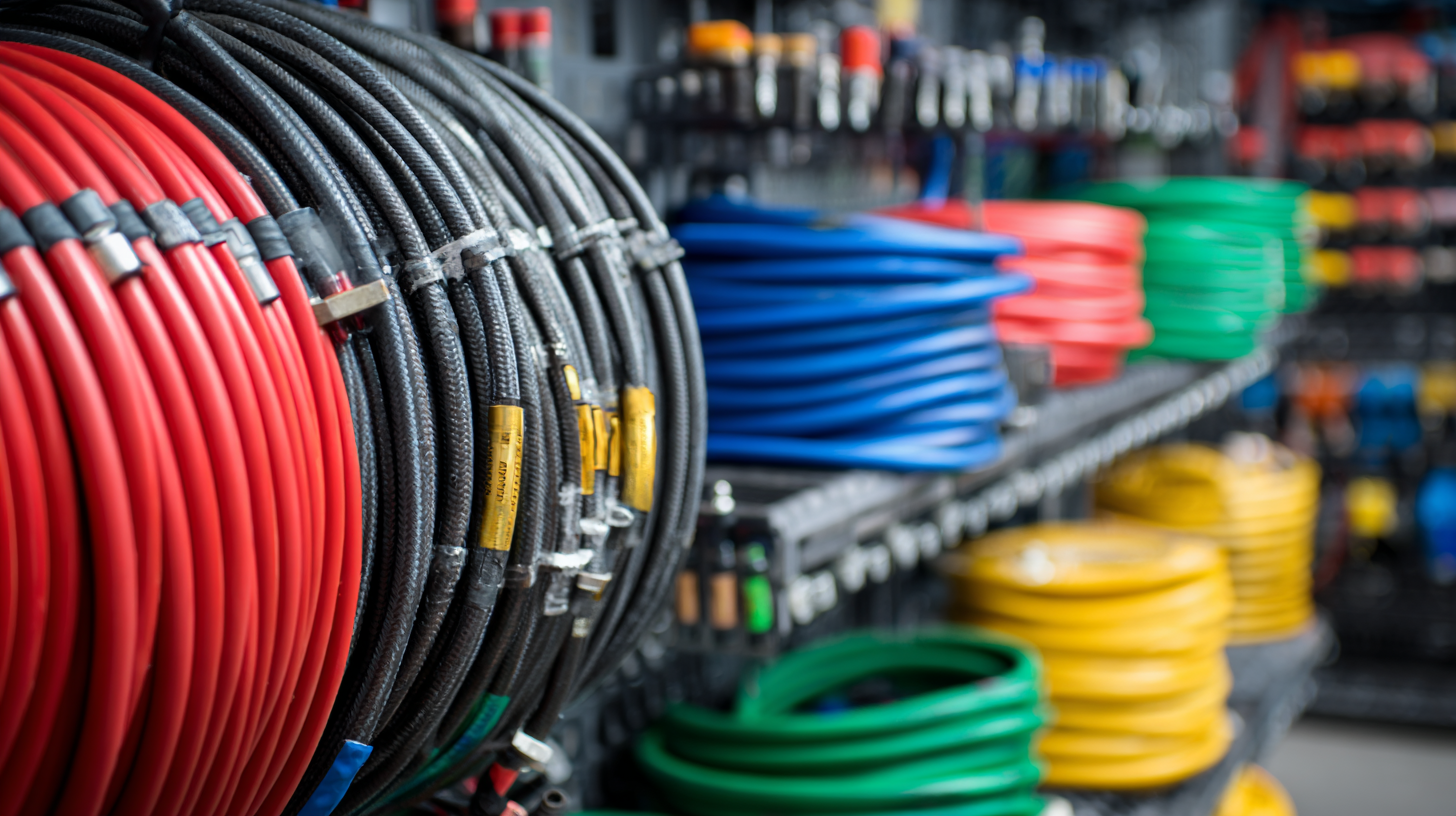

When selecting hose accessories for your business, it's crucial to understand the various types available, as they play a vital role in optimizing performance and safety. Common hose accessories include couplings, nozzles, fittings, and clamps. Couplings are essential for connecting hoses securely, ensuring a leak-proof environment, while nozzles help regulate the flow of fluid, providing versatility for different applications. Understanding the specific functions of each accessory allows businesses to tailor their hose systems to meet their operational needs effectively.

Another important category is hose reels and storage solutions, which help maintain organization and prolong the lifespan of the hoses. Proper storage can prevent wear and damage, reducing replacement costs over time. Additionally, specialized hose accessories like filters and regulators can enhance performance by preventing contaminants from entering the system and controlling pressure levels. By familiarizing yourself with these options, you can make informed decisions that enhance efficiency and reliability in your operations.

When selecting hose accessories for industrial applications, it's crucial to consider several key factors to enhance operational efficiency and safety. According to a report by the Industrial Hose Association, nearly 25% of equipment failures in manufacturing can be traced back to improper hose accessory selections. This highlights the importance of understanding specific business needs, including the types of materials being transported, the working environment, and pressure requirements.

Tips: Always evaluate compatibility between the hose and accessory materials. For instance, using a polyvinyl chloride (PVC) accessory with a rubber hose may lead to early degradation and unexpected leaks.

Additionally, consider the environmental conditions in which the hoses will operate. Temperature extremes, UV exposure, and potential chemical interactions are vital in determining the longevity of accessories. A study by the National Association of Hose Manufacturers revealed that businesses optimizing their accessory selections based on environmental factors could increase lifespan by up to 30%.

Tips: Review manufacturer specifications for temperature ranges and chemical resistance before making your purchase. Ensuring all components are rated for your specific application conditions will help prevent premature failures and costly downtimes.

| Accessory Type | Material | Working Pressure (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Hose Couplings | Aluminum | 150 | -40 to 200 | General Industrial |

| Hose Clamps | Stainless Steel | 200 | -40 to 300 | Automotive, HVAC |

| Quick Connects | Brass | 300 | -20 to 250 | Agricultural, Pneumatic |

| Barbed Fittings | Polypropylene | 150 | -40 to 200 | Irrigation, Chemical Transfer |

| Pressure Regulators | Cast Iron | 250 | -20 to 180 | Fluid Control |

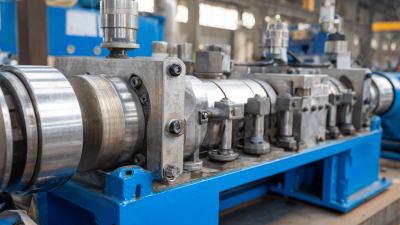

When it comes to selecting hose accessories for business operations, evaluating the durability of materials used is crucial. A recent report by Grand View Research highlights that the global hose accessories market is expected to reach $4 billion by 2025, driven significantly by the demand for more resilient materials. Businesses investing in high-quality hose accessories made from superior materials like thermoplastics and stainless steel stand to benefit from reduced maintenance costs and enhanced operational efficiency.

For example, accessories made from high-grade rubber or reinforced PVC can withstand extreme temperatures and pressures, making them ideal for industrial applications. According to a study conducted by the Society of Plastics Engineers, hoses constructed with durable materials can last up to three times longer than their counterparts made from inferior materials. This longevity not only translates into cost savings over time but also minimizes downtime related to equipment failures, thereby supporting seamless business operations. Businesses that prioritize material durability in their hose accessory selection not only ensure reliability but also enhance their overall productivity.

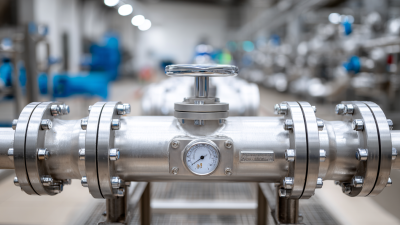

When selecting hose accessories for your business needs, understanding flow rates and pressure ratings is crucial for optimizing performance. According to a recent report by the Hose Manufacturers Association, nearly 60% of operational inefficiencies in fluid transfer systems can be attributed to mismatched hose accessories. Flow rates, defined as the volume of fluid that passes through the hose over time, directly impact the productivity of your operations. Selecting accessories that match or exceed the required flow rate can ensure consistent output, reducing the risk of bottlenecks in production.

Moreover, pressure ratings play a vital role in maintaining the integrity of your hose system. The American Society for Testing and Materials (ASTM) recommends always choosing accessories with a pressure rating at least 20% higher than the maximum operating pressure. This not only enhances safety but also extends the lifespan of the equipment. For example, while standard hoses may handle pressures up to 150 psi, using accessories rated for 250 psi can significantly reduce the likelihood of catastrophic failure, which is reported to cost businesses an average of $100,000 per incident in downtime and lost production.

When selecting hose accessories for your business, it's crucial to weigh the cost against the quality. While it might be tempting to choose the least expensive options, investing in high-quality accessories can lead to long-term savings by reducing the frequency of replacements and maintenance. Quality hose connectors, nozzles, and reels can enhance efficiency and productivity, ensuring that you can focus on your core operations rather than dealing with equipment failures.

Recent insights into garden hoses highlight the importance of considering both weight and water flow in your decision-making process. Lightweight and kink-resistant hoses not only ease the burden of handling but also improve water delivery efficiency, which is vital for various applications in business settings. By prioritizing these features in your hose accessories, you can make more informed decisions that align with your operational needs and budget constraints, ultimately contributing to a more effective and streamlined workflow.