MENUMENU

Choosing the right ball valves for your plumbing needs is a critical decision that can impact the efficiency and reliability of your systems. According to a recent industry report by the Global Ball Valves Market Analysis, the demand for high-quality ball valves is projected to grow at a CAGR of 5.2% from 2021 to 2026, underscoring their importance in various applications. These valves are pivotal in controlling the flow of liquids and gases, ensuring that systems perform optimally and safely.

Industry expert Dr. Emily Chen, a renowned authority in valve technologies, emphasizes the significance of selection in her research, stating, "The right choice of ball valves can significantly enhance system performance while reducing maintenance costs." As the plumbing industry evolves, the diversity of ball valves available can make the selection process daunting. Understanding the different types, materials, and specifications is essential for making informed decisions. This introduction aims to guide you through the crucial aspects of choosing the right ball valves that cater specifically to your plumbing requirements, ensuring both functionality and durability in your installations.

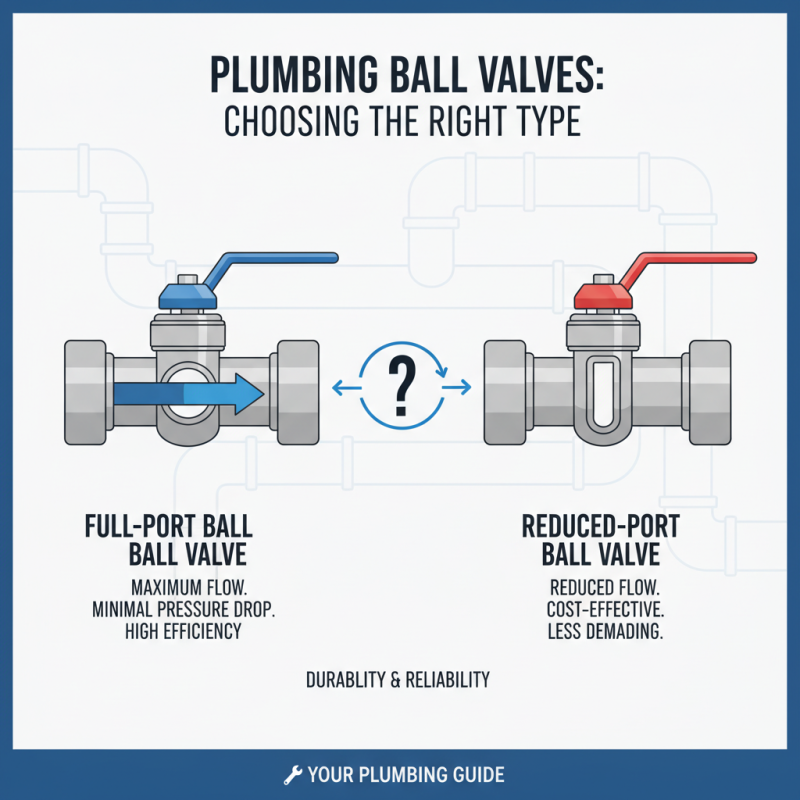

When selecting the right ball valves for plumbing applications, understanding the different types available is crucial. Ball valves, known for their durability and reliability, come in various designs, each serving distinct functions. The two main categories are full port and reduced port ball valves. Full port valves allow maximum flow with minimal pressure drop, making them ideal for applications where efficiency is a priority. In contrast, reduced port valves have a smaller opening, which can lead to a decrease in flow rate but offers a cost-effective solution for less demanding scenarios.

Another important distinction lies in the materials used to manufacture ball valves. Common materials include brass, stainless steel, and PVC. Brass and stainless steel valves are suitable for high-pressure and high-temperature applications due to their strength and resistance to corrosion. On the other hand, PVC valves are lightweight, resistant to chemicals, and cost-efficient, making them a popular choice for residential plumbing systems. Understanding these variations enables homeowners and professionals to select the most appropriate ball valve that meets the specific requirements of their plumbing needs.

When selecting ball valves for plumbing applications, one of the most critical factors to consider is the material used in their construction. Common materials include brass, stainless steel, plastic, and bronze, each offering distinct advantages tailored to specific plumbing scenarios. For instance, brass valves are known for their durability and resistance to corrosion, making them suitable for residential plumbing systems. Conversely, stainless steel valves offer superior strength and can withstand high temperatures and pressures, which makes them ideal for industrial applications.

Another important consideration is compatibility with the fluid being transported. For aggressive chemicals or corrosive substances, plastic ball valves may be preferred due to their resistance to corrosion and ability to handle a variety of chemicals without degrading.

Additionally, the temperature range of the application is essential, as materials like PVC may not perform well in high-temperature environments, whereas metals such as stainless steel can handle extreme conditions without compromising structural integrity.

Ensuring the right material choice not only enhances the longevity of the plumbing system but also ensures optimal functionality and safety in fluid transport.

When selecting ball valves for plumbing applications, one of the most critical factors to consider is the valve diameter, which significantly impacts flow rates and overall system performance. Larger diameter ball valves allow for greater flow capacity, as they reduce frictional loss and enhance fluid dynamics. According to industry data, a valve sized correctly for the application can maintain optimal flow with minimal pressure drop, highlighting the importance of precise sizing in plumbing systems.

Tips: When determining the appropriate ball valve size, consider the piping system's flow requirements and the nature of the fluid being transported. Tools like the Hydraulic Institute's guidelines recommend calculating the required flow rate and selecting a valve that meets or exceeds this requirement to ensure efficient operation.

Another crucial aspect to consider is the valve's Cv (flow coefficient), which indicates the flow rate through the valve at a given pressure drop. A higher Cv value translates to better flow capabilities, making it essential to match the valve size not only to the pipe diameter but also to the flow demands of the system. Properly sized ball valves can help maintain system efficiency and prevent issues such as cavitation or excessive pressure loss, which are common when mismatched components are used.

Tips: Always refer to flow charts and manufacturer data when choosing your ball valve, as these resources can provide insights into how different sizes and types of valves will perform under specific conditions.

| Diameter (Inches) | Flow Rate (GPM) | Max Pressure (PSI) | Material | Typical Application |

|---|---|---|---|---|

| 1 | 30 | 150 | Brass | Residential Plumbing |

| 1.5 | 50 | 150 | Stainless Steel | Commercial Plumbing |

| 2 | 100 | 200 | PVC | Irrigation Systems |

| 3 | 150 | 250 | Bronze | Industrial Systems |

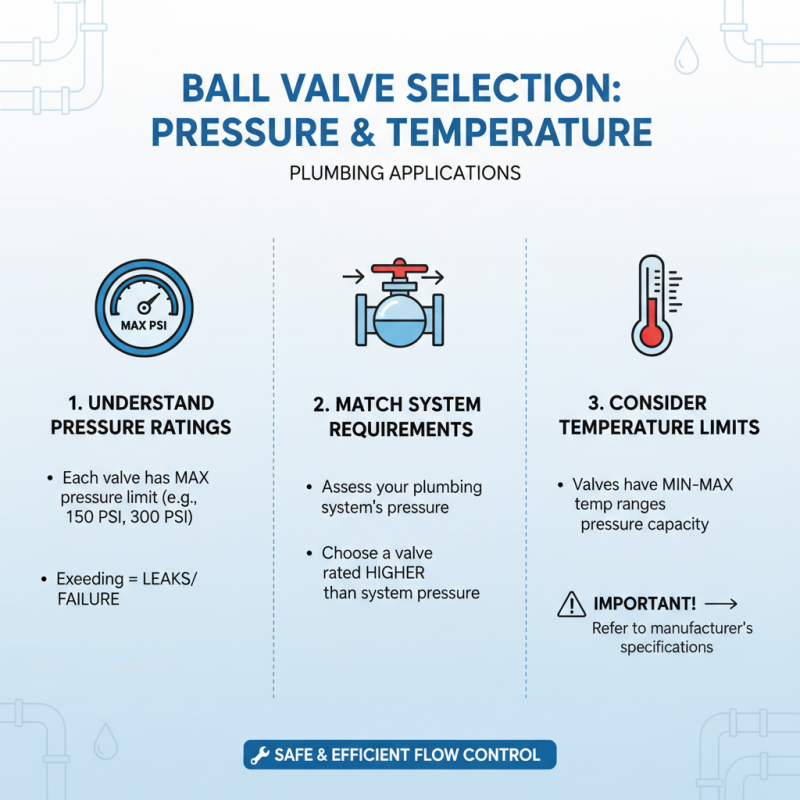

When selecting ball valves for plumbing applications, understanding pressure ratings and temperature limits is crucial. Ball valves are designed to control the flow of liquids and gases, and their effectiveness hinges on their ability to withstand specific pressure levels. Each valve type comes with a designated pressure rating, which indicates the maximum pressure the valve can handle without risking failure. It is essential to assess the pressure of your plumbing system to choose a valve that will operate safely and efficiently within that range. Exceeding the pressure rating can lead to leaks or catastrophic failures, underscoring the importance of this evaluation.

Temperature limits are equally significant when selecting ball valves. Each valve material can endure different temperature ranges; for instance, metal valves typically withstand higher temperatures than plastic ones. It is vital to consider the operating temperatures of the fluids being transported in your plumbing system. High temperatures can compromise valve integrity over time, leading to reduced performance or damage. By understanding both the pressure ratings and temperature limits of the ball valves under consideration, you can make an informed decision that ensures the longevity and reliability of your plumbing system.

When it comes to installing ball valves in plumbing systems, following best practices ensures optimal performance and longevity. First and foremost, it is crucial to select the appropriate size and type of ball valve for the specific application. Consider the pipe diameter, the fluid being transported, and the pressure and temperature conditions.

Once the right valve is chosen, installation should be done with precision. Ensure that all connections are clean and free of debris, and use the correct sealants or thread tapes to prevent leaks. It’s also important to install the valve in the correct orientation, as indicated by the flow arrow, to allow for proper function.

Maintenance of ball valves is equally important to uphold their efficiency and durability. Regular inspections should be planned to check for leaks, corrosion, or any signs of wear. Valves should be exercised periodically to prevent seizing, especially in systems that are not frequently used.

Additionally, lubricating the valve stem and inspecting the seals can extend the life of the valve. Keeping a detailed maintenance log can help identify any recurring issues and assist in scheduling timely servicing, ensuring that the plumbing system operates smoothly.