MENUMENU

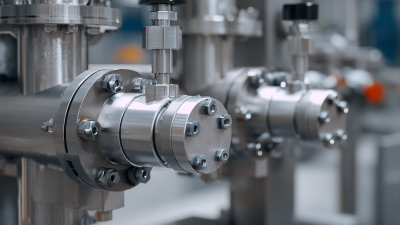

In the world of industrial automation, selecting the right valve actuator is crucial to ensuring the efficiency and reliability of operations. With a plethora of options available, each designed for specific applications and environments, making the correct choice can be overwhelming. From electric and pneumatic to hydraulic actuators, the right valve actuator not only influences the performance of your system but also impacts maintenance costs and safety.

In the world of industrial automation, selecting the right valve actuator is crucial to ensuring the efficiency and reliability of operations. With a plethora of options available, each designed for specific applications and environments, making the correct choice can be overwhelming. From electric and pneumatic to hydraulic actuators, the right valve actuator not only influences the performance of your system but also impacts maintenance costs and safety.

This blog will provide valuable tips on how to choose the right valve actuator tailored to your industrial needs, guiding you through key considerations such as compatibility, control requirements, and environmental factors. By the end of this guide, you'll be equipped with knowledge to make an informed decision, optimizing your processes and enhancing productivity.

When it comes to selecting a valve actuator for industrial applications, understanding the different types available in the market is crucial. Valve actuators primarily fall into three categories: electric, pneumatic, and hydraulic.

Electric actuators are popular for their precision and ease of integration with control systems. They are ideal for applications requiring automation and can handle a range of torque requirements, making them versatile across various industries. However, they may face limitations in harsh environmental conditions or where explosive gases are present.

Electric actuators are popular for their precision and ease of integration with control systems. They are ideal for applications requiring automation and can handle a range of torque requirements, making them versatile across various industries. However, they may face limitations in harsh environmental conditions or where explosive gases are present.

On the other hand, pneumatic actuators are renowned for their speed and reliability. They operate using compressed air, making them suitable for environments where rapid action is essential. Pneumatics are commonly utilized in applications like food processing and chemical manufacturing, where valve response times are critical. Meanwhile, hydraulic actuators offer powerful control and are perfect for high-force applications. Their ability to handle heavy loads makes them ideal for industries such as oil and gas, where robust operation is a necessity. Each type has its specific advantages and applications, helping industries make informed decisions based on operational needs.

When selecting a valve actuator for your industrial needs, there are several key factors to consider to ensure optimal performance and reliability. First, assess the type of valve you are working with. Different valves require specific actuators; for example, ball valves typically pair well with rotary actuators, while gate valves are more suited for linear actuators. Understanding the valve type helps in narrowing down your options significantly.

Next, consider the operational environment of the actuator. Factors such as temperature extremes, humidity, and exposure to corrosive substances can influence actuator choice. For harsh environments, you might need actuators with specialized coatings or protective enclosures. Additionally, evaluate the actuator’s power source—electric, pneumatic, or hydraulic—and how that aligns with your facility's existing infrastructure. The choice of power source will affect installation complexity, operational costs, and overall efficiency.

Finally, don’t overlook the control requirements of your system. Depending on your application, you may need an actuator with advanced controls for precise positioning or simpler options for on/off functionality. Ensure the actuator you choose can communicate effectively with your existing control systems, fostering seamless integration and improving operational efficiency.

Choosing the right valve actuator for your industrial needs requires a deep understanding of both actuator specifications and your system requirements. The first step in this process is to assess the specific functions your industrial system needs to perform. Consider factors such as the type of valve being controlled, the required torque and speed, and the environmental conditions the actuator will operate in. For instance, pneumatic actuators might be ideal for applications that require fast response times, while electric actuators could offer better precision in positioning.

In addition to performance capabilities, compatibility with existing systems is crucial. Evaluate the communication protocols used in your operations, as some actuators offer advanced features that integrate seamlessly with digital control systems. Furthermore, understanding the power supply options available and the space constraints in your facility will help narrow down your choices. By aligning actuator specifications with these industrial requirements, you can ensure optimal functionality and efficiency in your operations, ultimately leading to improved productivity and reduced downtime.

| Actuator Type | Torque Output (Nm) | Operating Pressure (bar) | Power Supply (V) | Control Type | Environment Rating |

|---|---|---|---|---|---|

| Electric | 100 | 6 | 230 | On/Off | IP67 |

| Pneumatic | 150 | 8 | N/A | Modulating | IP65 |

| Hydraulic | 200 | 12 | N/A | On/Off | IP68 |

| Manual | Varies | N/A | N/A | Manual | N/A |

When selecting a valve actuator for industrial applications, balancing quality and budget is crucial. A cost analysis can reveal a range of options from low-cost alternatives to high-end models. It's essential to assess not just the initial purchase price but also the overall lifecycle costs, including maintenance, efficiency, and reliability. For industries focused on environmental monitoring, affordable solutions like microfluidics can help streamline operations while minimizing expenses.

**Tip 1:** Start by defining your specific needs and operational requirements. Consider factors such as the type of fluids being controlled, pressure levels, and installation environment. This will narrow down your options and help you focus on what truly meets your demands.

**Tip 2:** Look beyond upfront costs. Evaluate the long-term value of quality actuators that may come with a higher price tag but offer superior durability and less frequent maintenance. Investing in reliable systems can lead to significant savings and improved productivity over time.

Making an informed choice on valve actuators involves careful consideration of both quality and cost. By analyzing your requirements and potential long-term expenses, you can find the right balance to suit your industrial needs effectively.

In the evolving landscape of industrial automation, selecting the right valve actuator is crucial, not just for immediate performance but also for ensuring future adaptability. Current trends in valve actuator technology highlight the growing emphasis on smart features and connectivity. Integrated sensors and IoT capabilities allow for real-time monitoring and data analytics, enabling predictive maintenance and optimized operation. Adopting these technologies can significantly minimize downtime and maintenance costs, aligning with the broader push for Industry 4.0 advancements.

Moreover, the shift towards energy-efficient solutions is reshaping the market. Manufacturers are increasingly focusing on actuators that consume less energy while maintaining high performance. Innovations such as electric actuators with battery backup and hybrid systems are making it easier for industries to contribute to sustainability goals without compromising on reliability. As the industry continues to embrace automation and digital solutions, selecting valve actuators that reflect these trends not only future-proofs business operations but also positions companies as leaders in their respective fields.