MENUMENU

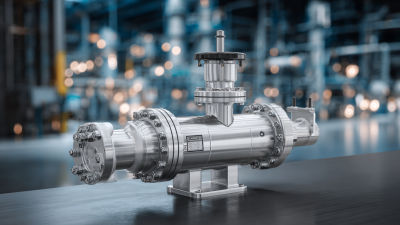

When it comes to maintaining the safety and efficiency of industrial systems, the selection of the appropriate high pressure relief valve is paramount. These valves play a critical role in controlling excess pressure and preventing catastrophic failures in pressurized systems. However, the task of choosing the right high pressure relief valve can be daunting due to the variety of types, materials, and specifications available in the market. It is essential to understand the specific requirements of your system, as well as the operating conditions, to ensure optimal performance and reliability.

In this guide, we will explore the key factors to consider when selecting a high pressure relief valve for your application. From understanding the pressure set points to evaluating material compatibility, each decision impacts not only safety but also the efficiency of operations. By recognizing the essential features and performance characteristics of high pressure relief valves, you will be better equipped to make an informed choice that aligns with your system needs. Ultimately, investing time in selecting the right valve can lead to enhanced safety, reduced downtime, and improved overall system performance.

High-pressure relief valves play a crucial role in ensuring the safety and efficiency of various industrial systems. According to a report by the American Society of Mechanical Engineers (ASME), approximately 50% of major industrial accidents can be attributed to the failure of pressure relief systems. These statistics emphasize the necessity of proper valve selection and maintenance to mitigate risks associated with overpressure scenarios. High-pressure relief valves are engineered to automatically release pressure when it exceeds a predetermined limit, thereby preventing catastrophic failures and protecting both personnel and equipment.

Understanding the importance of high-pressure relief valves extends beyond their basic operational function; it encompasses their design, functionality, and suitability for specific applications. The National Fire Protection Association (NFPA) outlines that an adequately sized and specified relief valve can greatly reduce the likelihood of hazardous incidents, improving overall system reliability. A 2022 industry report indicated that incorrectly sized relief valves could lead to costly downtime and repairs, with some incidents resulting in losses exceeding $1 million. This underscores the imperative for engineers and system designers to meticulously assess their operational needs and select the correct relief valves to ensure optimal performance and compliance with safety standards.

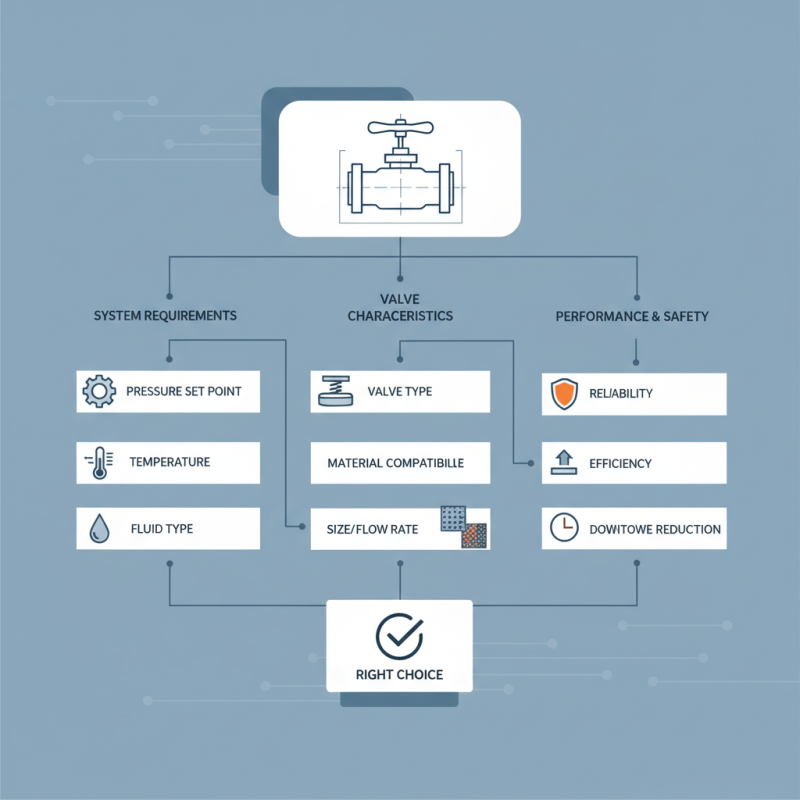

This chart illustrates the importance of different factors to consider when choosing high pressure relief valves for various systems. It includes parameters such as pressure rating, flow capacity, material compatibility, and response time.

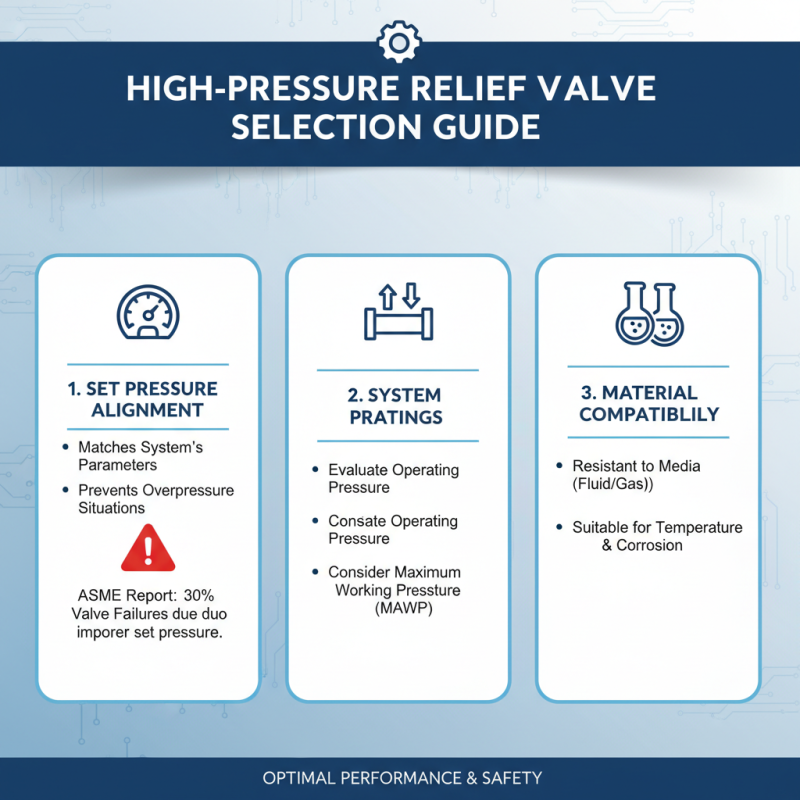

When selecting a high pressure relief valve for your system, several key factors warrant careful consideration to ensure optimal performance and safety. Firstly, the valve's set pressure must align with the system's operational parameters. According to a recent report by the American Society of Mechanical Engineers (ASME), improper set pressure is one of the leading causes of valve failure, accounting for nearly 30% of malfunction incidents in industrial settings. Therefore, evaluating the operating pressure and the maximum allowable working pressure (MAWP) of your system is crucial to prevent overpressure situations.

Another essential factor is the valve's material construction, which should match the media and operating conditions it will encounter. For example, corrosive substances require materials such as stainless steel or special alloys to maintain integrity under pressure. A study by the Pressure Relief Devices Group notes that nearly 25% of all pressure-related failures stem from material degradation due to inappropriate selection. Additionally, considering the size and connection type of the valve is vital; it should fit seamlessly within your existing piping infrastructure. This attention to detail will enhance efficiency and reliability, ultimately safeguarding your system against hazardous overpressure events.

High pressure relief valves (HPRVs) are essential components in various industrial systems, designed to protect equipment from overpressure conditions. There are several types of high pressure relief valves, each suited for specific applications. The most common types include spring-loaded relief valves, pilot-operated relief valves, and rupture discs.

Spring-loaded valves function based on the compression of a spring, suitable for many general applications. Pilot-operated valves use a small pilot valve to control a larger main valve, providing higher sensitivity and reduced leakage rates, often used in critical processes such as oil and gas production. Rupture discs, on the other hand, are sacrificial devices designed to burst at a predetermined pressure, providing a reliable means of pressure relief where traditional valves might fail.

When selecting the appropriate high pressure relief valve, consider the specific needs of your system. According to a recent report by the Pressure Relief Valve User Group, approximately 30% of industrial accidents are attributed to faulty pressure relief systems. Therefore, ensuring proper sizing and selection based on system requirements is critical.

Tips: Ensure that your selected valve can handle the maximum set pressure of your system. Regular maintenance and testing can prevent failures—aim for testing every six months as recommended by industry standards. Furthermore, be mindful of the installation environment; valves should be installed vertically for optimal performance, unless specified otherwise by manufacturer guidelines.

When selecting a high pressure relief valve for a system, proper sizing and capacity calculations are critical to ensure safety and efficiency. According to a report by the American Society of Mechanical Engineers (ASME), approximately 70% of pressure relief valve failures result from incorrect sizing. Thus, understanding the specific requirements of your system, including maximum operating pressure and flow rates, is essential. Factors such as the type of fluid, temperature, and pressure surges must be taken into account to determine the appropriate valve size.

To accurately size a pressure relief valve, engineers often use the formula Q = C * P * A, where Q represents the required flow rate, C is the valve coefficient based on the type of fluid, P is the pressure differential, and A is the area of the valve opening. Industry standards suggest that valves should be sized to handle at least 10% more than the calculated relief flow rate to provide a safety margin. Additionally, the National Board of Boiler and Pressure Vessel Inspectors recommends a periodic review of sizing calculations every five years, as changes in system dynamics can significantly impact relief valve performance. By adhering to these guidelines and utilizing appropriate data, professionals can ensure the effective operation of high pressure relief valves, ultimately enhancing system safety and reliability.

| Valve Type | Set Pressure (psi) | Capacity (SCFM) | Body Material | Orifice Size (inches) |

|---|---|---|---|---|

| Spring Loaded | 2000 | 250 | Stainless Steel | 1 |

| Pilot Operated | 3000 | 400 | Carbon Steel | 1.5 |

| Balanced Bellows | 1500 | 180 | Alloy Steel | 1.25 |

| Thermal Relief | 1000 | 130 | Polymer | 0.75 |

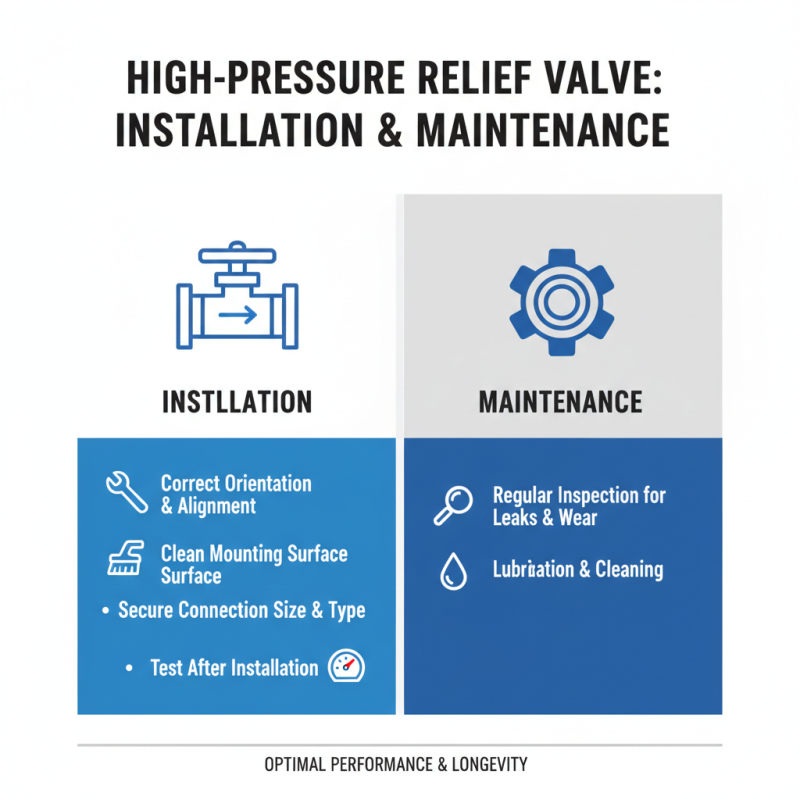

Proper installation and maintenance of high pressure relief valves are crucial for their optimal performance and longevity. When installing a relief valve, it is essential to ensure that the valve is correctly oriented, with the inlet and outlet aligned as specified by the manufacturer’s guidelines. Additionally, the mounting surface should be clean and free of debris to prevent any obstructions that could hinder the valve's operation. It is important to consider the connection size and type to avoid leaks and ensure a secure fit. Furthermore, testing the valve after installation is recommended to confirm that it opens and closes at the desired pressure settings.

Regular maintenance is equally vital to ensure that high pressure relief valves function effectively over time. Periodic inspections should be conducted to check for signs of wear, corrosion, or any obstructions. This includes examining the seating surface and spring condition, as these components are key to the valve's sealing capability. Lubrication of moving parts, when appropriate, can aid in maintaining the valve's responsiveness. Additionally, establishing a maintenance schedule that includes testing the valve under operational conditions will help identify any potential issues before they lead to system failures. By prioritizing these practices, users can enhance the reliability and performance of their high pressure relief valves significantly.