MENUMENU

As the industrial sector evolves, the demand for reliable and efficient flow control solutions intensifies, leading to significant advancements in valve technology. Among these, knife valves are increasingly recognized for their exceptional performance in various applications, particularly in handling slurries and viscous fluids. According to a recent market research report by Grand View Research, the global valve market is expected to reach USD 105.2 billion by 2025, with a notable increase in the adoption of specialized valves, including knife valves, which promise enhanced durability and low maintenance costs. This growth is driven by industries such as oil and gas, water treatment, and food processing, where precision and reliability are imperative. As we look towards 2025, the rise of innovative knife valve solutions is poised to reshape the landscape of industrial valve technology, ensuring optimal efficiency and safety in fluid management systems.

The industrial valve market is witnessing a significant transformation, particularly with the emergence of knife valves featuring innovative functionalities. According to the latest report by MarketsandMarkets, the global industrial valve market is projected to reach $85.7 billion by 2025, driven by the increasing demand for efficient flow control in various sectors. Among these, knife valves have gained prominence due to their ability to handle thick slurries and corrosive materials, making them indispensable in industries such as mining, wastewater treatment, and oil and gas.

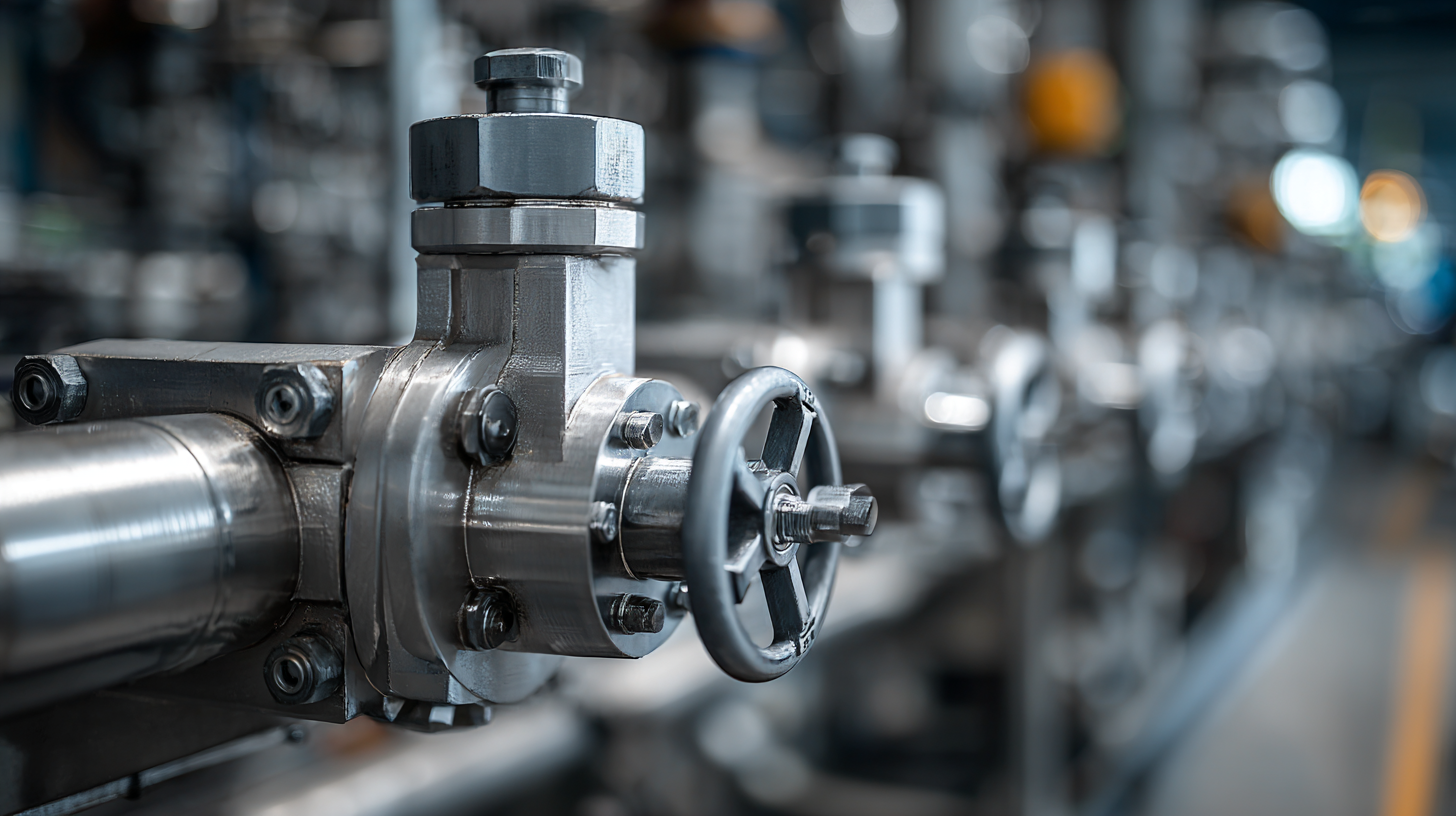

Recent advancements in knife valve technology are redefining performance standards. New designs incorporate features like high-strength materials, automated actuation, and enhanced sealing mechanisms that minimize leakage and improve operational reliability. A study by ResearchAndMarkets reveals that the increasing focus on energy efficiency and sustainability is further propelling the adoption of these advanced knife valve solutions. Additionally, predictive maintenance technologies are being integrated into valve systems, allowing for real-time monitoring and reducing downtime, ultimately leading to cost savings for manufacturers and operators alike.

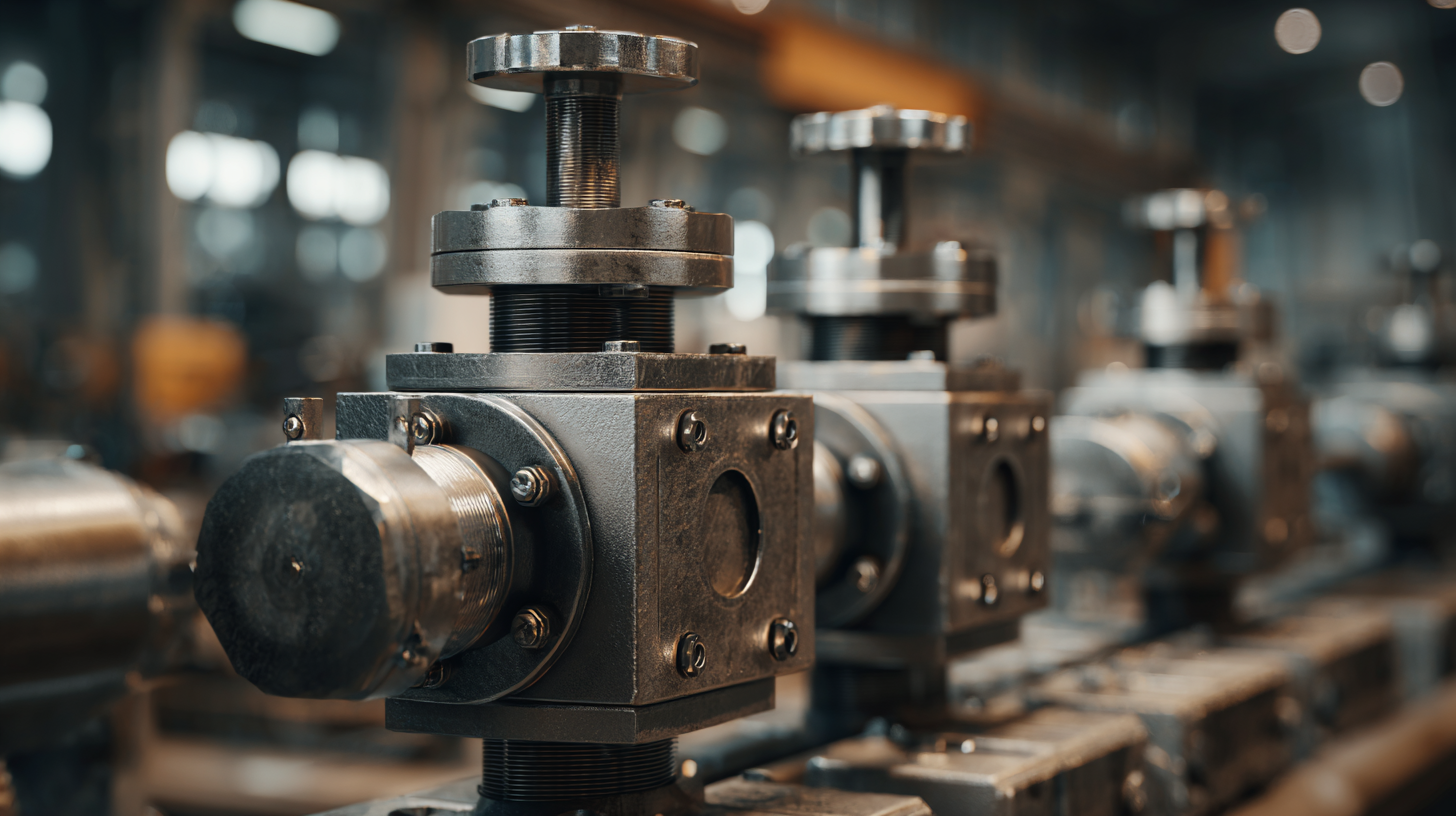

Selecting the right material for knife valve manufacturing is essential for ensuring durability, performance, and reliability in various industrial applications. Knife valves operate under demanding conditions, often dealing with abrasive and corrosive materials. Thus, the choice of material directly impacts the valve's lifespan and maintenance requirements. Stainless steel, for example, is widely favored for its excellent resistance to corrosion, while specialty alloys like duplex or super duplex steels are preferred in applications that require extra strength and resistance to pitting and stress corrosion cracking.

Another crucial aspect of material selection is its compatibility with the media being handled. For instance, in industries like oil and gas, where valves might come into contact with hydrocarbons or harsh chemicals, choosing materials that maintain structural integrity and prevent contamination is paramount. Additionally, thermoplastic materials are gaining attention for specific applications due to their lightweight nature and resistance to chemical exposure, presenting a viable alternative for certain scenarios. As advancements in material science continue, the development of innovative materials will drive the evolution of knife valve technology, leading to enhanced performance and efficiency in the industrial sector.

| Material Type | Corrosion Resistance | Temperature Range (°C) | Pressure Rating (PSI) | Applications |

|---|---|---|---|---|

| Stainless Steel | Excellent | -50 to 300 | 1500 | Oil & Gas, Water Treatment |

| Ductile Iron | Good | -40 to 200 | 1000 | Wastewater, HVAC |

| PVC | Fair | -15 to 60 | 220 | Chemical Processing, Irrigation |

| Titanium | Excellent | -250 to 400 | 3000 | Aerospace, Marine |

| Carbon Steel | Poor | -29 to 400 | 1500 | Power Generation, Oil & Gas |

In the evolving landscape of industrial valve technology, a comparative analysis between knife valves and traditional valve solutions reveals significant advantages that can influence operational efficiency.

Knife valves, designed for cutting through various types of media, offer a unique mechanism that allows for tighter seals and reduced leakage. This capability makes them particularly advantageous in applications involving slurries, viscous fluids, and other challenging materials. Unlike traditional valves, which often struggle with wear and tear over time, knife valves are built to withstand harsher environments, providing longevity and reliability.

Moreover, the simple design of knife valves contributes to ease of maintenance and efficiency. Traditional valves may require complicated actuator mechanisms, which can complicate maintenance procedures and increase downtime. In contrast, knife valves typically feature a straightforward, robust design that allows for quicker disassembly and repair.

With industries moving towards more streamlined operations, the knife valve emerges as a practical solution, bridging the gap between durability and low operational costs, ultimately positioning itself as a favored choice for many manufacturers and operators in 2025 and beyond.

As we look toward 2025, the industrial valve sector is on the brink of a significant transformation, particularly with knife valve technology. Emerging technologies are not only streamlining the production processes but also enhancing the performance and reliability of knife valves. Innovations such as smart sensors and IoT integration are enabling real-time monitoring of valve conditions, thereby improving operational efficiency and minimizing downtime. These advancements are crucial in sectors where precision and safety are paramount.

Tips for Choosing the Best Knife Valve Solutions:

As these technologies evolve, knife valves will play an essential role in meeting the demands of various industries, ensuring they remain a critical component in fluid control applications.

The rise of knife valve solutions in industrial applications is increasingly evident across various sectors, highlighting their effectiveness in handling thick and abrasive materials. One remarkable case study can be observed in the pulp and paper industry, where a notable manufacturer integrated knife valves into their processes. This transition not only reduced maintenance costs but also improved operational efficiency. The ability of knife valves to provide a tight seal ensured minimal leakage and waste during the production cycle, significantly boosting the company's sustainability efforts.

In the chemical processing sector, another success story emerges from a company that faced challenges with traditional valve systems prone to clogging and inefficiency. By implementing advanced knife valve technology, they streamlined their handling of viscous liquids. The design of these valves, which allows for easy cleaning and maintenance, proved invaluable, leading to significantly decreased downtime. As industries continue to seek optimized solutions for fluid control, the widespread adoption of knife valves is set to transform operational frameworks, enhancing both versatility and performance.