MENUMENU

In the fast-evolving world of manufacturing and engineering, selecting the right tubing connectors is a critical decision that can significantly impact the success of your projects. As industry expert Dr. Emily Chen, a leading researcher in fluid dynamics, once stated, "The efficiency and durability of any system heavily rely on the quality and compatibility of its tubing connectors." This highlights the necessity of understanding the various types of connectors available and their specific applications.

Choosing the appropriate tubing connectors involves considering factors such as material compatibility, pressure ratings, and connection mechanisms. In an era where precision engineering and reliability are paramount, making informed choices can help prevent costly downtime and ensure the smooth operation of your systems. Whether you are working on medical devices, aerospace applications, or industrial machinery, a thoughtful approach to tubing connectors will ultimately enhance performance and safety.

As we delve into the 2025 guide, we will explore essential criteria for selecting the right tubing connectors for your projects. By examining industry trends, latest innovations, and expert recommendations, you will be equipped with the knowledge needed to make successful, effective decisions that align with your specific project requirements. Understanding the intricacies of tubing connectors not only safeguards your project’s integrity but also paves the way for future advancements in your field.

When it comes to tubing connectors, understanding the types available and their specific applications is crucial for ensuring an efficient and effective project. Tubing connectors are versatile components that facilitate the joining of different tubing sections, allowing for the seamless transfer of fluids or gases. Common types include barbed connectors, which provide a secure hold for flexible tubing, and compression fittings, which are ideal for rigid tubes. Each design offers distinct advantages, depending on the materials being joined and the environmental conditions they will face.

In industrial applications, quick-disconnect connectors are favored for their convenience, allowing for speedy assembly and disassembly without compromising flow integrity. For high-pressure scenarios, flared fittings can provide a robust seal that withstands significant force, making them suitable for hydraulic systems. Additionally, in precision applications such as laboratories, specialized connectors are employed to ensure that contaminants do not interfere with sensitive processes. Understanding these various connectors helps in choosing the right type for your project, enhancing both safety and performance in system operations.

When selecting tubing connectors for your projects, several key factors should be evaluated to ensure optimal performance and compatibility. First, consider the material of the connectors, as this will significantly influence their durability and resistance to environmental factors. Materials such as plastic, metal, or rubber each have their unique properties; plastic connectors are lightweight and corrosion-resistant, making them suitable for various applications, while metal connectors provide enhanced strength and can withstand higher pressures.

Another critical aspect to assess is the size and compatibility of the connectors with the tubing you plan to use. It’s essential to match the inner diameter of the connector with that of the tubing to prevent leaks and ensure a secure fit. Additionally, the specific application requirements—such as pressure ratings, temperature tolerance, and fluid type—should guide your selection process. For instance, connectors designed for high-pressure applications must meet stringent safety and reliability standards to function effectively in demanding environments. By carefully considering these factors, you can select tubing connectors that not only meet your project needs but also contribute to its overall success.

| Connector Type | Material | Temperature Range (°C) | Pressure Rating (psi) | Application |

|---|---|---|---|---|

| Compression Fitting | Brass | -20 to 120 | 4000 | General Purpose |

| Barbed Connector | Plastic | -10 to 80 | 150 | Low Pressure Systems |

| Quick Connect | Stainless Steel | -40 to 180 | 3000 | Industrial Applications |

| Elbow Connector | PVC | 0 to 60 | 200 | Drainage Systems |

| Tee Connector | Aluminum | -20 to 150 | 2500 | Fluid Distribution |

When choosing tubing connectors for your projects, understanding the material choices available is essential for ensuring the performance and longevity of your system. Common materials for tubing connectors include plastic, metal, and rubber, each offering distinct advantages that can influence your decision based on the application requirements.

Plastic connectors, such as those made from PVC or polyethylene, are lightweight, resistant to corrosion, and generally more cost-effective, making them ideal for low-pressure applications or systems that require frequent assembly and disassembly.

Metal connectors, typically crafted from stainless steel or aluminum, provide excellent strength and durability, making them suitable for high-pressure environments and applications where longevity and reliability are critical.

On the other hand, rubber connectors offer flexibility and sealing capabilities, which can be particularly beneficial in applications where vibrations or minor movement are expected.

Selecting the right material for your tubing connectors not only impacts the functionality of your system but also enhances its overall efficiency. By carefully considering the environmental conditions, pressure levels, and potential wear and tear, you can choose connectors that best meet your project's specific needs, ensuring both optimal performance and cost-effectiveness over time.

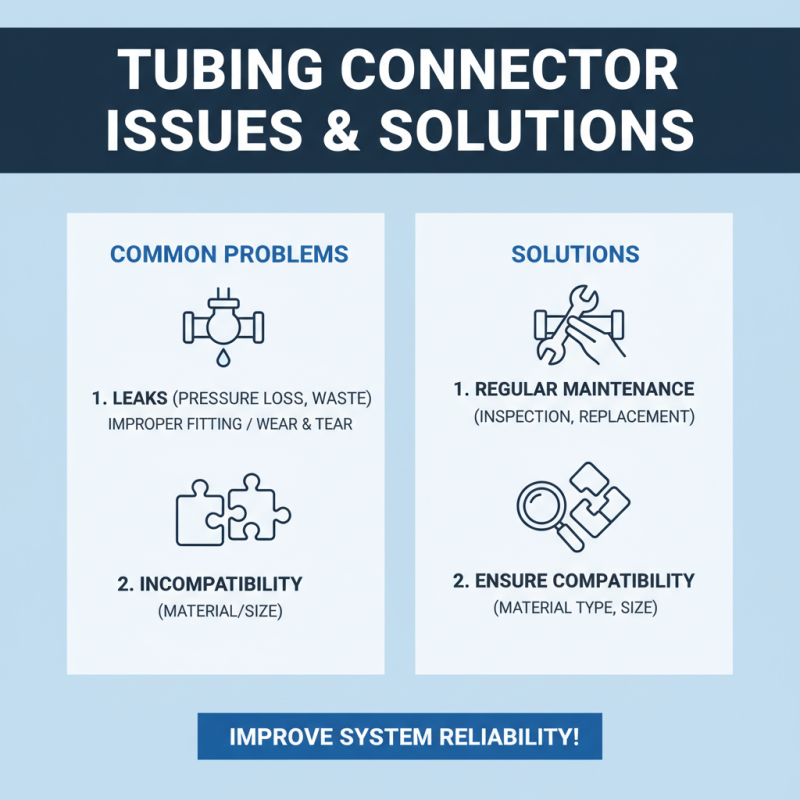

When working with tubing connectors, various issues can arise that may hinder the efficiency and effectiveness of your projects. One common problem is the occurrence of leaks between connectors, which can lead to pressure loss and material waste. This often happens due to improper fitting or wear and tear over time. To address this issue, ensure that connectors are compatible with the tubing material and check for any signs of damage. Regular maintenance and replacement of worn-out components can prevent leaks and improve overall system reliability.

Another frequent concern is the misalignment of connectors, which can disrupt the flow and lead to blockages. This issue can often be mitigated by carefully aligning connectors during assembly and securing them adequately. Utilizing appropriate alignment tools and fixtures can ensure a proper fit. Additionally, incorporating flexible connectors can help accommodate any discrepancies in alignment, thereby maintaining a smooth flow in the system. By proactively addressing these common tubing connector issues, you can enhance the performance and durability of your projects.

When it comes to installing and maintaining tubing connectors, following best practices can significantly enhance system performance and longevity. According to a report by the International Society of Automation, improper installation can lead to leaks that cost industries billions annually, emphasizing the importance of precision and care in handling these components. Ensuring that tubing connectors are compatible with the materials used in your project is crucial; according to data from the Fluid Power Journal, compatibility issues account for approximately 15% of system failures in hydraulic applications.

Routine maintenance is equally important for the optimal functioning of tubing connectors. Regular inspections to check for wear, corrosion, and proper alignment can help prevent unexpected downtimes. The Hydraulic Institute recommends a maintenance schedule that includes cleaning connector surfaces and replacing worn-out seals. A study from the American Society of Mechanical Engineers highlights that implementing a proactive maintenance strategy can extend connector lifespan by up to 30%, ultimately saving costs and improving operational efficiency. By adhering to these best practices, companies can enhance the reliability and safety of their tubing systems.